Unexpected Solution Improves Organic Solar Cells

- An unknown material, made from disulfide flakes has helped to boost the power of organic solar cells.

Carbon-based semiconductor molecules, commonly used in OPVs, offer more advantages over silicon. OPVs are more flexible. Meaning they can be made on a large scale with low-cost and roll-to-roll printing. The best OPVs can convert 17% of light they capture to electrical power, which is well short of what commercial silicon cells offer at 20%.

Thomas D. Anthopoulos worked with some colleagues at KAUST Solar Center on OPVs. They estimated that OPVs can potentially rival the performance of silicon if certain aspects of the cell were enhanced. When light reaches the semiconductor, electrons are freed from the material which leaves positively charged holes.

Both items are gathered by different phases on the opposite faces of the semiconductor before they are delivered to the electrodes in the cell to generate current. The hole transporter is called PEDOT: PSS. It is acidic and can absorb moisture from the air, which in turn degrades other properties in the solar cell.

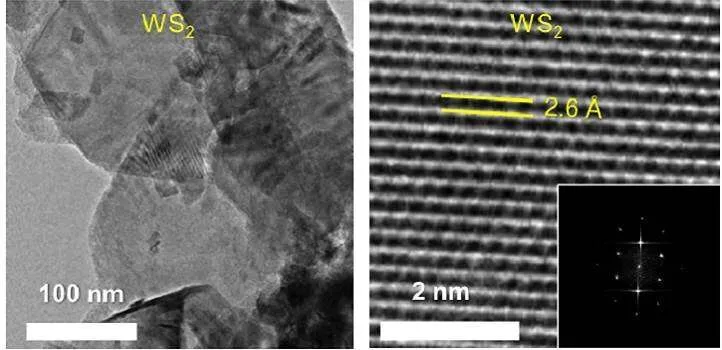

Anthopoulos and the interdisciplinary team at KAUST have made a hole-transporting layer from flakes of tungsten disulfide. They achieved this by using ultrasound to split the flakes off tungsten disulfide that was suspended in water and ethanol an inexpensive method that is easy to scale up, allowing the flakes to spread into an electrode via a spin-coating process. Anthopoulos fabricated several OPVs the best of which had a power conversion rate of 17%, which is arguably the highest for OPVs when a 2-D material is used as a hole transporter.

Also read