Swansea group on a roll with published perovskite solar cells

- Scientists have reported the highest possible efficiency tape-recorded for full roll-to-roll published perovskite solar cells, an advancement noting an essential step towards cheaper and a lot more reliable methods of generating solar energy.

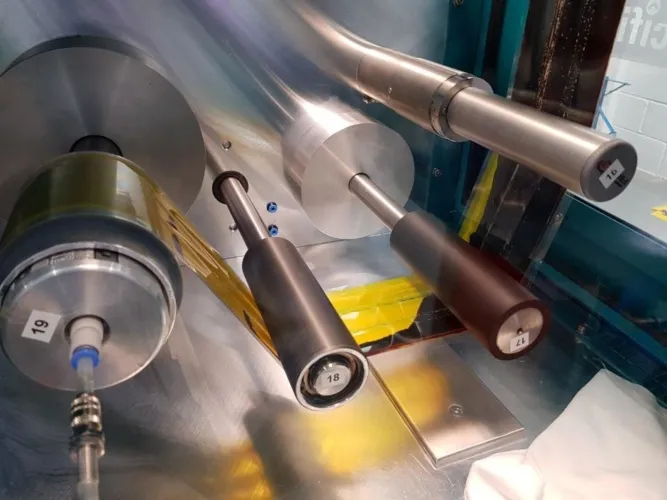

A group at Swansea University's SPECIFIC Innovation and also Knowledge Centre, led by Professor Trystan Watson, has actually reported utilizing a roll-to-roll construction approach for 4 layers of slot-die covered PSCs.

Printed perovskite solar cell shows industry charm

The PSCs offered the stable power result of 12.2 per cent, which is the highest possible efficiency recorded for four layers of roll-to-roll published PSCs to day.

In comparison to silicon photovoltaics (PV), which call for heat and high vacuum cleaner depositions, PSCs can be solution-processed at a reduced temperature, which makes it feasible to utilize plastic substratums to produce adaptable solar cells.

According to SPECIFIC, the capacity to solution-process offers the opportunity to apply well-developed printing and also finishing techniques consisting of screen, inkjet and gravure printing, plus slot-die and spray covering.

These advantages made it possible for Swansea University scientists to make use of roll-to-roll production for 4 layers of PSCs.

Slot-die layer is a pre-metred strategy, which suggests the wet film density can be controlled before finish. It is additionally very efficient in material usage, with very little loss of product compared with spray finishing or display printing.

Using the necessary poisonous solvents at an industrial scale calls for a lot of air handling to stay under safety and security restrictions, which can incur considerable costs. Therefore, an acetonitrile-based system was used. This system has a rheological benefit because of reduced viscosity as well as reduced surface area stress, which results in much better coatings.

In addition to this, a ternary blend of high work environment exposure restriction solvents was introduced, changing chlorobenzene for the deposition of hole transport material. In this study, the PSCs provided the steady power outcome of 12.2 percent.

A total solar cell for a selected architecture calls for finishing 5 layers. At SPECIFIC, 4 layers were coated using slot-die finishing and also the top get in touch with was placed on using thermal evaporation. Slot-die covering the fifth (top) contact without destroying any layers below has actually not yet been accomplished and solving this would allow the manufacture of a totally roll-to-roll printed PSC.

In a statement, Rahul Patidar of SPECIFIC, lead scientist on the project, said: "Perovskite solar cells intend to increase the performance and reduced the price of traditional solar energy generation. They have the prospective to be highly effective as well as reasonably cheap to produce, so the goal is to improve fabrication approaches for upscaling. This research signifies the following step towards commercialisation."

Also read