Solar perovskite manufacturing on a roll

- High-performance perovskite solar cells are used a manufacturing-friendly liquid-based process suitable for roll to roll production.

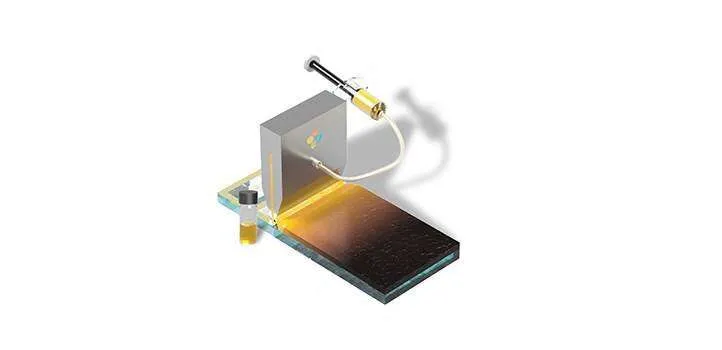

Advanced ink solutions could be the secret to transforming perovskite solar cells (PSCs) from heroes of academic laboratories into commercially effective items. Scientists at KAUST have created a perovskite ink custom-made for a mass manufacturing process called slot-die finish, generating PSCs that captured solar power with high effectiveness. The ink can additionally be coated onto silicon to create perovskite/silicon tandem solar cells that record even more of the sun's energy.

" PSCs have shown a lot of assurance in lab-scale work over the past decade," claims Anand Subbiah, a postdoc in Stefaan De Wolf's laboratory. "As an area, we require to begin taking a look at the security and scalability of PSC modern technology," he claims.

PSCs made in study laboratories are commonly made by spin-coating, which is inadequate to mass manufacture. Slot-die coating, in contrast, is a production strategy made use of industrially for nearly 70 years. "The process entails continually and also exactly forcing an ink with a slim slit that is crossed the substratum to create a constant film," Subbiah says. "This high-throughput method would enable roll-to-roll construction, similar to publishing papers."

To generate high-efficiency slot-die layered PSCs, the team faced numerous difficulties. A few of the best-performing spin-coated PSCs incorporate the perovskite with a poly( triarylamine) (PTAA) transportation layer, yet PTAA is hydrophobic and also extremely repellent to fluid perovskite ink. Including a surfactant to the ink formula conquered the repellence, causing much better high quality user interface as well as films and also much better device efficiency, Subbiah states. The group additionally switched the ink to a lower-boiling solvent, decreasing ink drying time without the requirement for more processing actions.

Generally, the group's maximized slot-die layered PSCs captured solar power with approximately 21.8 percent performance, a significant renovation over the 18.3 percent formerly taped for PSCs made by doing this.

Much more significantly, from a business perspective, was that the ink might readily be covered onto textured silicon to produce a perovskite/silicon tandem solar cell, Subbiah claims. "We were also able to make the really first slot-die covered silicon-perovskite monolithic tandem solar cell, recording a 23.8 percent effectiveness," he claims.

" The advancement of scalable deposition techniques for perovskite solar cells is important to bring this modern technology from the study labs to the market," De Wolf claims. "Our following steps are making large-area devices and components using our industrialized modern technology and evaluating their stability in the lab and the outdoors, while remaining to improve efficiency."

Also read