Recently established solar materials could introduce ultrathin, lightweight photovoltaic panel

- A race is on in solar engineering to produce nearly impossibly-thin, flexible solar panels. Designers visualize them made use of in mobile applications, from self-powered wearable devices as well as sensors to lightweight aircraft and also electrical vehicles.

Versus that backdrop, researchers at Stanford University have actually attained record performances in an encouraging team of solar materials.

Chief amongst the advantages of these change metal dichalcogenides-- or TMDs-- is that they take in ultrahigh levels of the sunlight that strikes their surface contrasted to various other solar materials.

" Think of an independent drone that powers itself with a solar array atop its wing that is 15 times thinner than a piece of paper," stated Koosha Nassiri Nazif, a doctoral scholar in electrical engineering at Stanford and also co-lead writer of a study published in the Dec. 9 edition of Nature Communications. "That is the assurance of TMDs."

The look for new products is necessary since the reigning king of solar materials, silicon, is much too hefty, bulky and stiff for applications where flexibility, lightweight and also high power are leading, such as wearable devices and also sensors or aerospace and also electric vehicles.

" Silicon makes up 95 percent of the solar market today, but it's much from best. We require new products that are light, flexible as well as, frankly, more eco-friendly," claimed Krishna Saraswat, a teacher of electrical engineering and senior writer of the paper.

A competitive alternative

While TMDs hold terrific pledge, research experiments to day have actually battled to transform more than 2 percent of the sunlight they absorb into electricity. For silicon photovoltaic panels, that number is closing in on 30 percent. To be made use of widely, TMDs will have to close that space.

The new Stanford prototype achieves 5.1 percent power conversion effectiveness, however the writers project they can virtually reach 27 percent performance upon optical and also electrical optimizations. That figure would certainly be on par with the most effective solar panels on the marketplace today, silicon consisted of.

Additionally, the prototype realized a 100-times higher power-to-weight ratio of any kind of TMDs yet established. That ratio is important for mobile applications, like drones, electric vehicles and the capacity to bill expeditionary equipment on the move. When looking at the details power-- a procedure of electrical power outcome each weight of the solar cell-- the prototype generated 4.4 watts per gram, a figure affordable with other current-day thin-film solar cells, including other speculative prototypes.

" We believe we can increase this essential ratio an additional 10 times via optimization," Saraswat claimed, adding that they approximate the functional limitation of their TMD cells to be an impressive 46 watts per gram.

Extra advantages

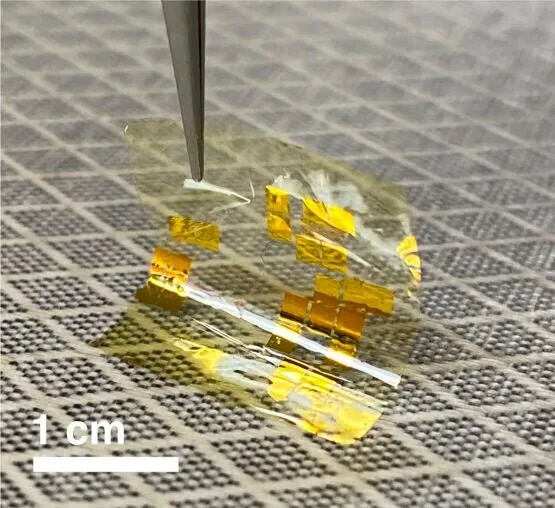

Their largest advantage, nevertheless, is their exceptional thinness, which not just lessens the product usage and price yet also makes TMD solar cells lightweight and flexible and also with the ability of being formed to irregular forms-- a car roof, an aircraft wing or the human body. The Stanford team was able to produce an active selection that is just a couple of hundred nanometers thick. The variety includes the photovoltaic TMD tungsten diselenide and get in touches with of gold extended by a layer of carrying out graphene that is just a solitary atom thick. All that is sandwiched between a flexible, skin-like polymer and an anti-reflective coating that boosts the absorption of light.

When totally set up, the TMD cells are less than 6 microns thick-- regarding that of a lightweight workplace trash bag. It would take 15 layers to reach the thickness of a solitary piece of paper.

While thinness, lightweight and also flexibility are all very desirable goals in and of themselves, TMDs present various other engineering advantages too. They are stable and also dependable over the long-term. As well as unlike other oppositions to the thin-film crown, TMDs consist of no hazardous chemicals. They are also biocompatible, so they could be made use of in wearable applications requiring straight contact with human skin or tissue.

An appealing future

The many benefits of TMDs are countered by particular disadvantages, mostly in the engineering details of mass production. The process of moving an ultrathin layer of TMD to a flexible, supporting material commonly harms the TMD layer.

Alwin Daus, that was co-lead author on the research study with Nassiri Nazif, created the transfer process that attaches the thin TMD solar arrays to the flexible substratum. He stated this technical obstacle was significant. One step included transferring the layer of atomically thin graphene onto a flexible substrate that is simply a couple of microns thick, clarified Daus, that was a postdoctoral scholar in Eric Pop's research group at Stanford when the research study was performed. He is currently an elderly scientist at RWTH Aachen University in Germany.

This complex process results in the TMD being completely embedded in the flexible substrate causing higher resilience. The researchers evaluated the flexibility and robustness of their gadgets by bending them around a metal cylinder less than a third of an inch thick.

"Powerful, flexible as well as long lasting, TMDs are an appealing brand-new direction in solar technology," Nassiri Nazif wrapped up.

Added Stanford co-authors of this work include Stanford professor Eric Pop and also Ada Poon in Electrical Engineering; Mark Brongersma in Materials Science & Engineering; checking out scholar Sam Vaziri; postdoctoral scholar Raisul Islam; and college students Jiho Hong, Nayeun Lee, Aravindh Kumar, Frederick Nitta, Michelle E. Chen and Siavash Kananian.

Also read

- UbiQD Secures Landmark Quantum Dot Deal with First Solar

- Astronergy Invests $53M in Tandem Solar Cell Project

- ARENA Unveils $39M Solar Innovation Funding Round

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record