Printed security for perovskite cells

- Scientists led by the University of Cambridge have created a brand-new approach to print a protective layer of copper straight onto a perovskite solar cell, supplying protection to the energetic layer from damages frequently created in later manufacturing phases. Cells using this layer were evaluated in various tandem mixes with silicon cells and achieved a maximum efficiency of 24.4%.

The recent progression in perovskite solar cell efficiencies has been well documented, and also the innovation appears to have gotten on the edge of major industrial production for a few years now.

One of the major concerns still holding perovskites back, nevertheless, is the fragility of the perovskite layer itself. This has actually usually been shown to be sensitive to moisture as well as various other conditions cells are likely to encounter in the field, and they can likewise endure damages as the various other layers are deposited on top of it.

The sputtering procedure frequently made use of to deposit a transparent electrode layer onto the perovskite is a certain trouble right here. Several options currently exist to prevent damages to the perovskite during this process. Researchers at the University of Cambridge, nevertheless, have actually taken a different technique to the problem, which they claim will open up brand-new opportunities for extremely effective, semi-transparent perovskite devices.

Copper oxide

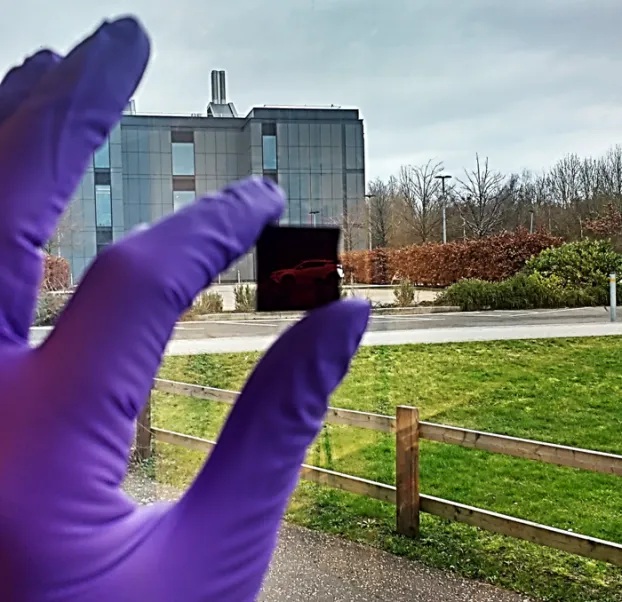

The team established a procedure to 'print' a layer of copper oxide onto the perovskite. The layer can be deposited at a reduced temperature level using a method that does not damage it. As well as also at only 3 nanometers thick, the copper oxide layer was revealed to safeguard the perovskite from damaging throughout the sputtering of the clear conductive oxide. The process is described in the paper Rapid Vapor-Phase Deposition of High-Mobility p-Type Buffer Layers on Perovskite Photovoltaics for Efficient Semitransparent Devices, released in ACS Energy Letters.

" Key to success is the ability of their oxide growth method to duplicate the high quality of precise, vacuum-based strategies, but in open air and much quicker," checks out a statement from the university. "This decreases any damages to the perovskite while making sure that the oxide grown has high thickness, such than only a very slim layer is required."

Perovskite solar cells made with this copper oxide layer achieved maximum performances of 16.7%. The translucent cells were incorporated right into tandem gadgets with silicon cell modern technologies consisting of p-type PERC as well as the n-type 'syndicate' cells establish by the Solar Energy Research Institute of Singapore (SERIS). A four-terminal tandem using the SERIS solar cell accomplished a maximum effectiveness of 24.4%.

Cambridge says that its deposition method for copper oxide can possibly be scaled up for business manufacturing, and that its research study represents a brand-new strategy to silicon/perovskite tandem cell combination, that will likewise allow the advancement of various other gadgets requiring top quality protective layers.

Also read