New Cost Model Targets Efficient Tandem Solar Production

- Discover how NREL's innovative cost model for perovskite/silicon tandem solar modules could revolutionize efficiency and affordability, making solar energy more accessible than ever!

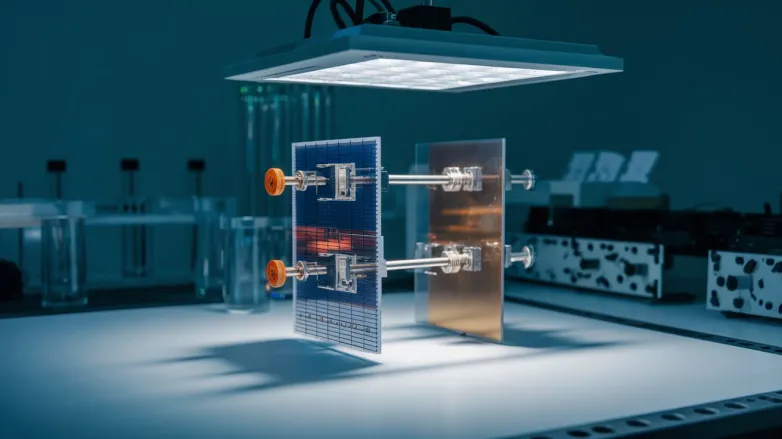

Researchers at the U.S. Department of Energy's National Renewable Energy Laboratory (NREL) have developed a comprehensive manufacturing cost model for perovskite/silicon tandem solar modules, highlighting the interplay between module efficiency and manufacturing capacity in driving down costs. Their findings reveal that improvements in module efficiency can yield cost reductions comparable to doubling factory size, emphasizing the potential of this new solar technology.

The Detailed Cost Analysis Model (DCAM) allows for a thorough examination of various manufacturing methods and factors affecting costs, such as factory location and production efficiency. The study indicates that achieving at least 25% efficiency is crucial for tandem modules to remain competitive in the solar market. Moving forward, the key challenges include enhancing the reliability and scalability of these tandem modules for commercial viability.

How does manufacturing efficiency influence costs for perovskite/silicon tandem solar modules?

- Definition of Manufacturing Efficiency: Manufacturing efficiency refers to optimizing the production process to minimize waste, reduce costs, and maintain or improve product quality. Higher efficiency can lead to reduced unit costs, making products more economically viable.

- Cost Reduction Mechanism: As manufacturing efficiency increases, the cost per watt of energy produced by perovskite/silicon tandem solar modules decreases. This is due to the ability to produce more modules in less time with fewer resources, thereby spreading fixed costs over more units.

- Economies of Scale: When manufacturing processes become more efficient, they can operate at larger scales without a proportional increase in costs. Scaling up production allows manufacturers to take advantage of bulk purchasing and optimize labor resources, further driving down costs.

- Comparison with Silicon Solar Modules: Traditional silicon solar cells may have established economies of scale, whereas perovskite/silicon tandem modules are still emerging. Efficient manufacturing practices could enable these new technologies to compete on cost with traditional options.

- Importance of Material Utilization: Enhanced manufacturing efficiency often leads to better material utilization. In perovskite/silicon tandem modules, reducing material waste during production can significantly impact overall cost, particularly because perovskite materials can be more expensive or less readily available than traditional silicon.

- Impact of Production Technology: Different production methods (e.g., roll-to-roll printing or vapor deposition) can exhibit varying levels of efficiency. Choosing the right technology not only affects efficiency but also the qualities of the final product, influencing costs indirectly through yield rates.

- Module Performance and Lifespan: Higher manufacturing efficiency can result in higher-quality tandem modules that are more reliable and have longer lifespans. This improves the cost-effectiveness of the investment for homeowners and businesses, making solar energy more attractive.

- Research and Development Investments: Continued investment in R&D aimed at improving manufacturing processes can provide long-term cost benefits. Innovations can lead to breakthroughs that lower production costs even more, enhancing competitiveness in the solar market.

- Regulatory and Site Considerations: The location of manufacturing facilities plays a critical role in operational costs. Regions with favorable policies, resources, and labor costs can improve overall manufacturing efficiency, further driving down end-user prices for solar modules.

- Challenges in Scaling Production: While enhancing efficiency can lead to cost reductions, it must be complemented by addressing scalability issues. Finding solutions to produce tandem modules at large volumes while maintaining efficiency is essential for market penetration.

- Future of the Solar Market: The interplay between manufacturing efficiency and cost is crucial for the adoption of perovskite/silicon tandem solar modules. If costs can be successfully lowered while maintaining or enhancing efficiency, these modules have the potential to gain significant market share in the growing renewable energy sector.

Also read