'Molecular glue' makes perovskite solar cells significantly extra trustworthy in time

- A research study group from Brown University has made a significant action towards improving the long-lasting reliability of perovskite solar cells, an emerging clean energy technology.

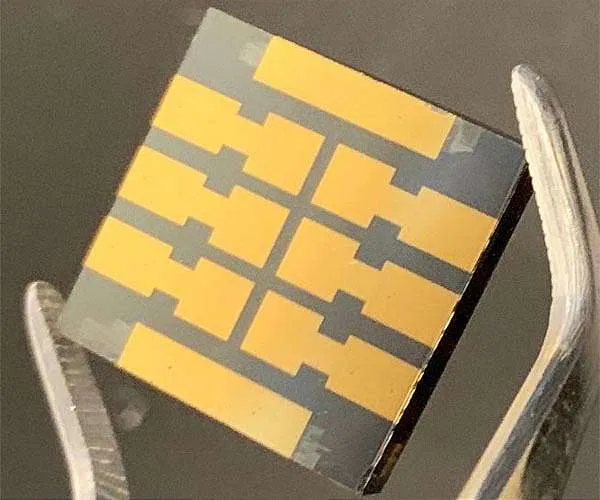

In a study to be released on Friday, May 7 in the journal Science, the group demonstrates a "molecular glue" that maintains a vital user interface inside cells from breaking down. The treatment significantly raises cells' stability and also integrity gradually, while additionally boosting the effectiveness with which they convert sunshine into electricity.

" There have actually been great strides in boosting the power-conversion performance of perovskite solar cells," said Nitin Padture, a professor of engineering at Brown University and also senior author of the new research. "However the last difficulty to be cleared prior to the modern technology can be commonly available is dependability - making cells that preserve their performance with time. That is among things my research team has actually been working on, and also we enjoy to report some crucial progression."

Perovskites are a class of products with a certain crystalline atomic structure. A little over a decade back, scientists revealed that perovskites are very good at absorbing light, which set off a flooding of new study into perovskite solar cells. The effectiveness of those cells has raised quickly and now measures up to that of traditional silicon cells.

The difference is that perovskite light absorbers can be made at close to area temperature level, whereas silicon needs to be grown from a thaw at a temperature coming close to 2,700 levels Fahrenheit. Perovskite movies are likewise regarding 400 times thinner than silicon wafers. The family member convenience of the manufacturing procedures and the use of much less product suggests perovskite cells can be possibly made at a portion of the expense of silicon cells.

While the performance improvements in perovskites have been exceptional, Padture claims, making the cells a lot more secure as well as trustworthy has remained challenging. Part of the issue has to do with the layering called for to make a working cell. Each cell contains five or even more distinctive layers, each performing a different feature in the electricity-generation procedure. Because these layers are made from different products, they respond in different ways to exterior forces.

Also, temperature changes that happen during the production process and also during solution can create some layers to expand or acquire more than others. That produces mechanical stresses at the layer interfaces that can trigger the layers to decouple. If the user interfaces are jeopardized, the performance of the cell plummets.

The weakest of those user interfaces is the one in between the perovskite film utilized to soak up light and also the electron transport layer, which keeps present flowing through the cell.

" A chain is just as strong as its weakest web link, as well as we recognized this user interface as the weakest part of the whole stack, where failing is most likely," said Padture, who directs the Institute for Molecular and also Nanoscale Advancement at Brown. "If we can reinforce that, after that we can begin materializing enhancements in dependability."

To do that, Padture made use of his experience as a product researcher, developing innovative ceramic finishes used in airplane engines as well as various other high-performance applications. He and his coworkers began experimenting with compounds known as self-assembled monolayers or SAMs.

" This is a large course of substances," Padture stated. "When you transfer these on a surface, the molecules construct themselves in a single layer as well as stand like short hairs. By using the ideal solution, you can form strong bonds between these substances and all sort of various surfaces."

Padture and his group located that a formula of SAM with silicon atom on one side, and also iodine atom on the various other, can create solid bonds with both the political election transportation layer (which is normally constructed from tin oxide) and also the perovskite light-absorbing layer. The team hoped that the bonds developed by these molecules could strengthen the layer user interface. And they were right.

" When we presented the SAMs to the interface, we found that it enhances the crack durability of the interface by about 50%, suggesting that any type of fractures that form at the interface often tend not to multiply very much," Padture claimed. "So basically, the SAMs become a kind of molecular glue that holds both layers together."

Testing of solar cell function showed that the SAMs significantly enhanced the practical life of the perovskite cells. Non-SAM cells prepared for the study preserved 80% of its initial efficiency for around 700 hrs of laboratory screening. At the same time the SAM cells were still going strong after 1,330 hours of testing. Based upon these experiments, the researchers forecast the 80%- retained-efficiency life to be about 4,000 hours.

" Among the other things we did, which people do not generally do, is we broke open the cells after screening," said Zhenghong Dai, a Brown doctoral trainee as well as initial writer of the study. "In the control cells without the SAMs, we saw all type of damages such as voids and splits. However with the SAMs, the unbreakable user interfaces looked actually great. It was a dramatic improvement that really type of surprised us."

Notably, Padture claimed, the improvement in strength did not come with the cost of power-conversion performance. Actually, the SAMs in fact boosted the cell's efficiency by a percentage. That occurred due to the fact that the SAMs eliminated little molecular defects that form when both layers bond in the absence of SAMs.

" The initial rule in boosting the mechanical stability of useful devices is 'do no injury,'" Padture stated. "To ensure that we could enhance integrity without shedding effectiveness - and even boosting efficiency - was a great shock."

The SAMs themselves are made from conveniently offered compounds and are easily applied with a dip-coating process at room temperature level. So the enhancement of SAMs would possibly add little to the production price, Padture claimed.

The researchers plan to improve this success. Now that they have actually fortified the weakest link in the perovskite solar cell pile, they would love to relocate onto the following weakest, after that the next and so forth up until they've strengthened the entire stack. That work will entail reinforcing not just the interfaces, however additionally the product layers themselves. Recently, Padture's study team won a $1.5 million grant from the UNITED STATE Department of Energy to increase on their study.

"This is the sort of study that's required in order to make cells that are low-cost, effective and also do well for decades," Padture stated.

Also read

- UbiQD Secures Landmark Quantum Dot Deal with First Solar

- Astronergy Invests $53M in Tandem Solar Cell Project

- ARENA Unveils $39M Solar Innovation Funding Round

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record