Low-Cost Perovskite Solar Cells: Nickel-Doped Graphite Solution

- Explore the potential of cost-effective perovskite solar cells. Researchers from multiple institutions have developed an alternative to using costly metals with a nickel-doped graphite layer and a bismuth-indium alloy layer, enabling a simple painting process for low-cost fabrication. With the potential to reduce manufacturing costs by up to 1000x, solar energy may become more accessible.

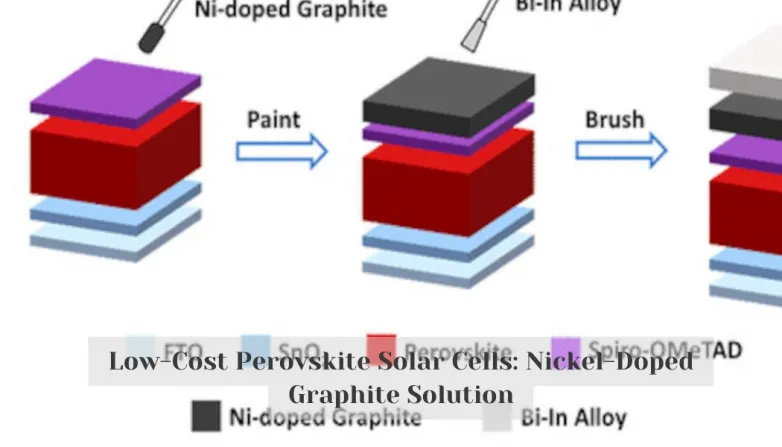

Researchers from multiple institutions, including Northern Illinois University, NREL, Northwestern University, and Argonne National Laboratory, have developed a cost-effective alternative to using precious metals in perovskite solar cells. They replaced the expensive gold or silver layer with a nickel-doped graphite layer combined with a bismuth-indium alloy layer. This substitution allows for a low-cost fabrication method, as the layers can be easily integrated into the perovskite device through a simple painting process. By eliminating the need for expensive materials and high-temperature vacuum processes, this innovation could significantly reduce the infrastructure investment required for perovskite solar cell production and expedite their commercialization.

The researchers achieved a power conversion efficiency of 21.0% using the new bilayer back electrode configuration. Although the efficiency is slightly lower than that of precious metal-based perovskites, which can reach 26%, the cost reduction potential outweighs this trade-off. The elimination of the precious metal layer in perovskite solar cells has the potential to reduce manufacturing costs by a factor of 4 to 1,000 for the contact electrodes in a gigawatt-scale perovskite-based solar plant, depending on other back materials used. This advancement paves the way for more affordable and accessible solar energy solutions.

Can Nickel-Doped Graphite Lower Perovskite Solar Cell Costs?

- Nickel-doped graphite combined with a bismuth-indium alloy layer can be used as an alternative to expensive gold or silver layers in perovskite solar cells

- This substitution allows for a low-cost fabrication method as the layers can be easily integrated into the perovskite device via a simple painting process

- Achieved a power conversion efficiency of 21.0% using the new bilayer back electrode configuration

- Cost reduction potential outweighs the trade-off of slightly lower efficiency (26%) when compared to precious metal-based perovskites

- Elimination of the precious metal layer in perovskite solar cells has the potential to reduce manufacturing costs by a factor of 4 to 1,000 for the contact electrodes in a gigawatt-scale perovskite-based solar plant

- Advancement paves the way for more affordable and accessible solar energy solutions

Also read