Losing weight on silver

- Using an ingenious high-speed video clip arrangement, researchers in Germany had the ability to observe the screen-printing process utilized in solar cell metallization, on a time scale of less than 50 milliseconds. Insights into the paste's behavior and the mechanisms at the workplace during display printing will improve the procedure as well as the formulation of the silver paste it relies upon.

Solar cells utilize silver in the metallic 'fingers' screen published onto their front sides, that transport fee generated in the silicon out into module and consequently into the power system. Some professionals anticipate that for solar to advance its impressive development trajectory, the sector will quickly call for the majority of the world's silver manufacturing in order to keep making modules.

As well as while alternatives such as light weight aluminum or copper are increasingly gaining ground, minimizing the amount of silver eaten per cell supplies a temporary solution. Wishing to attain this by decreasing the size of the fingers and also determining alternate paste formulations that could achieve far better conductivity with less silver, researchers at Germany's Karlsruher Institute of Technology set out to obtain a much better understanding of just how different paste make-ups behave during the screen-printing procedure.

Honest electronic camera

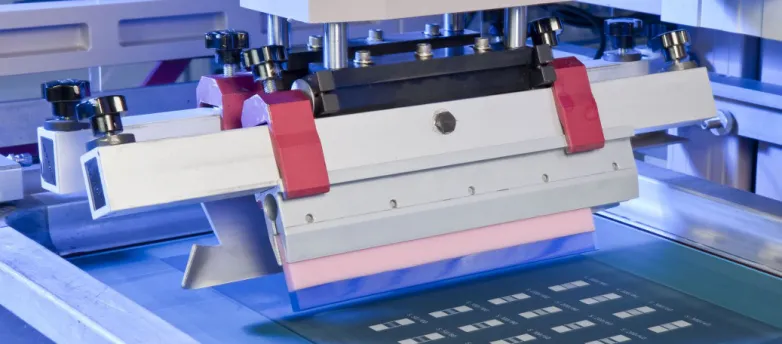

The group geared up a commercial display printer (made by Germany company ASYS) with a cam able to capture the process at 1,000 frameworks per secondly. The procedure was captured with 2 different paste compositions as well as numerous different procedure specifications, and the group took place to evaluate every one, checking out both the procedure video clip and also the metallized cell itself. They presented their lead to "Front side metallization of silicon solar cells-- A high-speed video clip imaging analysis of the screen-printing process," which was lately released in Solar Energy Materials and Solar Cells.

The research study revealed that oftentimes, current business pastes depend on ingredients to achieve necessary morphology and printer compatibility. Yet these do not burn off totally, leaving residuals that can reduce paste conductivity. The group additionally observed multiple phases within the procedure, consisting of paste spreading out resulting in (unwanted) boosted line size.

KIT plans to proceed this research with more paste structures, as well as will especially focus on differing wetting and also circulation properties in upcoming work. "This will certainly make it possible for the advancement of rational ideas promoting additional improvements of silver paste formula for silicon solar cell front-side metallization," the scientists claimed.

Also read