IBM Research Discovers new Battery That Could Trump Li-ion

- IBM Research has unveiled a new battery that could help eliminate the need for heavy metals in production and surpass the capabilities of Li-ion batteries

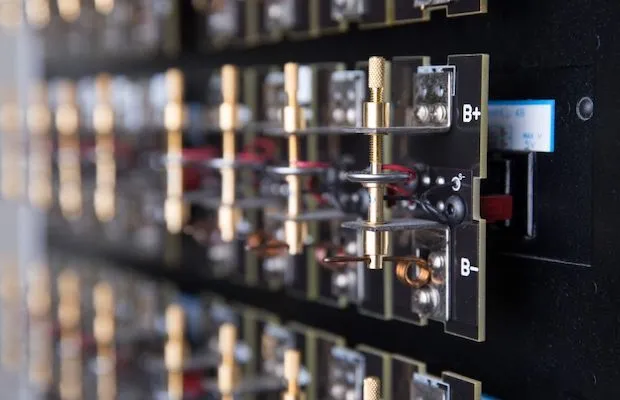

IBM Research is building on a long history of materials science innovation to unveil a new battery discovery. This new research could help eliminate the need for heavy metals in battery production and transform the long-term sustainability of many elements of our energy infrastructure.

As battery-powered alternatives for everything from vehicles to smart energy grids are explored, there remain significant concerns around the sustainability of available battery technologies.

Many battery materials, including heavy metals such as nickel and cobalt, pose tremendous environmental and humanitarian risks. Cobalt in particular, which is largely available in central Africa, has come under fire for careless and exploitative extraction practices.

Using three new and different proprietary materials, which have never before been recorded as being combined in a battery, the team at IBM Research has discovered chemistry for a new battery that does not use heavy metals or other substances with sourcing concerns. The materials for this battery are able to be extracted from seawater, laying the groundwork for less invasive sourcing techniques than current material mining methods.

Just as promising as this new battery’s composition is its performance potential. In initial tests, it proved it can be optimised to surpass the capabilities of lithium-ion batteries in a number of individual categories including lower costs, faster charging time, higher power and energy density, strong energy efficiency and low flammability.

New battery design could outperform lithium-ion across several sustainable technologies

Discovered in IBM Research’s Battery Lab, this design uses cobalt and nickel-free cathode material, as well as a safe liquid electrolyte with a high flash point. This unique combination of the cathode and electrolyte demonstrated an ability to suppress lithium metal dendrites during charging, thereby reducing flammability, which is widely considered a significant drawback for the use of lithium metal as an anode material.

This discovery holds significant potential for electric vehicle batteries, for example, where concerns such as flammability, cost and charging time come into play. Current tests show that less than five minutes are required for the battery – configured for high power – to reach an 80 percent state of charge. Combined with the relatively low cost of sourcing the materials, the goal of a fast-charging, low-cost electric vehicle could become a reality.

Overall, this battery has shown the capacity to outperform existing lithium-ion batteries not only in the previously listed applications, but can also be optimised for a range of specific benefits, including:

Lower cost: The active cathode materials tend to cost less because they are free of cobalt, nickel, and other heavy metals. These materials are typically very resource-intensive to the source, and also have raised concerns over their sustainability.

Faster charging: Less than five minutes required to reach an 80 percent state of charge (SOC), without compromising specific discharge capacity.

High power density: More than 10,000 W/L. (exceeding the power level that lithium-ion battery technology can achieve).

High energy density: More than 800 Wh/L, comparable to the state-of-art lithium-ion battery.

Excellent energy efficiency: More than 90 percent (calculated from the ratio of the energy to discharge the battery over the energy to charge the battery).

Low flammability of electrolytes

Also read