A blast of gas for better solar cells

- A basic procedure for transferring silicon oxide onto silicon wafers could be a fantastic progression for making silicon-based solar cells. Researchers at KAUST have utilized a method called plasma processing in a chamber filled with carbon dioxide gas.

The semiconducting component silicon is the product of option for around 90 percent of solar cell production. When the silicon is doped with chosen pollutants, the power from sunlight can kick electrons into creating a flow of electric present.

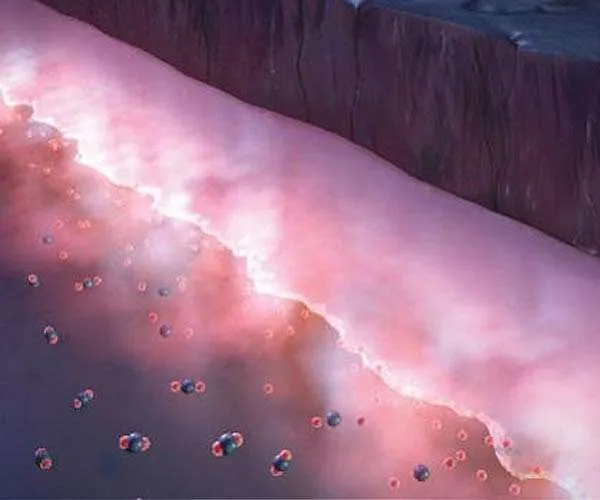

A technological obstacle arises, nevertheless, at the subjected surface of the silicon, described by Areej Alzahrani, a KAUST Ph.D. trainee, as the trouble of "dangling bonds." She describes that the reduced availability of silicon atoms to bond together at the surface leaves scope for electrons expelled by light power to recombine with the favorably billed "holes" that the leaving electrons leave.

This problem can be dealt with by generating a layer of silicon oxide at the surface area regions used to develop electrical get in touches with in a chemical procedure called passivation. Numerous methods can attain this, yet they all include troubles as well as constraints. They additionally introduce an additional and also expensive manufacture step. "The problems with existing methods tested us to discover a much more straightforward and functional procedure," states Alzahrani.

The solution includes subjecting the silicon to carbon dioxide in plasma-- a low temperature ionized gas. This allows controlled deposition of silicon oxide, followed by the overlaying of another silicon layer, as needed for the style of a solar cell. Attaining both these steps in the same chamber uses a significant decrease in manufacturing prices. "This simple and also straightforward procedure could be of excellent usage to the solar cell sector," Alzahrani concludes.

She points out that the team was surprised by the control that the approach attains over the deposition of an ultrathin silicon oxide layer with the needed microstructure. It also creates oxide films that are extra secure at heats, conquering an additional trouble with existing techniques. Tests exposed the procedure allows high voltages and also reduced electrical resistance, as needed for effective performance.

Currently the group has actually shown the fundamental technique, it prepares to relocate to create its commercial capacity. "An initial step will certainly be to incorporate this process right into a total and also working solar cell, while also exploring improved light-capturing designs," says research team leader, Stefaan De Wolf.

Also read