World first principle for rechargeable cement-based batteries

- Imagine a whole 20-storey concrete building that can save energy like a gigantic battery. Thanks to one-of-a-kind research study from Chalmers University of Technology, Sweden, this vision can sooner or later be a truth. Researchers from the Department of Architecture and Civil Engineering lately published a short article laying out a brand-new idea for rechargeable batteries made from concrete.

The ever-growing demand for lasting building materials presents wonderful challenges for researchers. Doctor Emma Zhang, formerly of Chalmers University of Technology, Sweden, signed up with Professor Luping Tang's study group several years ago to search for the structure products of the future. With each other, they have actually now developed a world-first principle for a rechargeable cement-based battery.

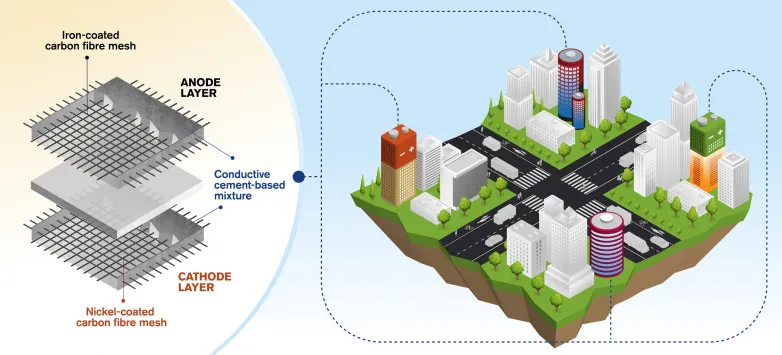

The idea includes a cement-based combination with percentages of short carbon fibres contributed to enhance the conductivity and flexural toughness. Embedded within the mix is a metal-coated carbon fibre mesh-- iron for the anode, and nickel for the cathode. After much testing, this is the prototype the researchers currently present.

" Results from earlier studies examining concrete battery technology revealed extremely low efficiency, so we understood we needed to consider of the box ahead up with one more way to generate the electrode. This specific concept that we have developed-- which is additionally rechargeable-- has never ever been discovered before. Currently, we have evidence of concept at lab scale," Emma Zhang clarifies.

Luping Tang and Emma Zhang's research study has generated a rechargeable cement-based battery with an ordinary energy density of 7 Watthours per square metre (or 0.8 Watthours per litre). Energy density is utilized to share the ability of the battery, and a small price quote is that the performance of the new Chalmers battery could be greater than 10 times that of earlier attempts at concrete batteries. The energy density is still reduced in contrast to industrial batteries, however this constraint could be overcome thanks to the substantial volume at which the battery could be built when made use of in structures.

A prospective key to resolving energy storage space concerns

The reality that the battery is rechargeable is its crucial quality, and the applications that can result if the idea is further created would be groundbreaking. Energy storage space is an apparent possiblity, surveillance is an additional. The researchers see applications that might vary from powering LEDs, offering 4G links in remote areas, or cathodic defense versus rust in concrete framework.

" It might also be coupled with solar cell panels, for instance, to give electrical energy and end up being the energy resource for checking systems in highways or bridges, where sensing units operated by a concrete battery might identify splitting or corrosion," suggests Emma Zhang.

The idea of using frameworks and buildings in this way would certainly supply an alternative solution to the energy crisis by providing a big quantity of energy storage.

Concrete, which is created by blending concrete with various other components, is the globe's most commonly utilized structure material. From a sustainability perspective, it is far from perfect, yet the possible to add power performance could supply a new measurement. Emma Zhang claims, "We have a vision that in the future, this technology might permit entire areas of multi-storey buildings made of practical concrete. Taking into consideration that any concrete surface area might have a layer of this electrode embedded, we are speaking about substantial volumes of functional concrete."

Challenges continue to be with service-life elements

The concept is still at a really beginning. The technological concerns staying to be resolved prior to commercialisation of the strategy include extending the life span of the battery and the development of recycling techniques. "Given that concrete facilities is normally built to last 50 or even 100 years, the batteries would certainly require to be refined to match this, or to be simpler to exchange and recycle when their life span is over. In the meantime, this uses a significant obstacle from a technological point of view," says Emma Zhang.

"We are persuaded this principle produces a fantastic contribution to allowing future building materials to have additional functions such as renewable energy resources," wraps up Luping Tang.

Also read

- Atmos Finalizes Funding for 100-MW Merredin Battery Project

- RPC, Greenfield Win Approval for Vale of Glamorgan Battery Storage

- Self-Assembling Molecule Breakthrough Brings Commercial Perovskite Solar Closer to Market

- Ignitis Unveils Ambitious 291-MW Battery Buildout Across Lithuanian Renewable Sites

- Renova Secures Financing for 30-MW Battery Project