Transparent graphene electrodes may result in brand-new generation of solar cells

- A brand-new method of making huge sheets of top quality, atomically thin graphene could lead to ultra-lightweight, adaptable solar cells, and to new courses of light-emitting devices as well as various other thin-film electronic devices.

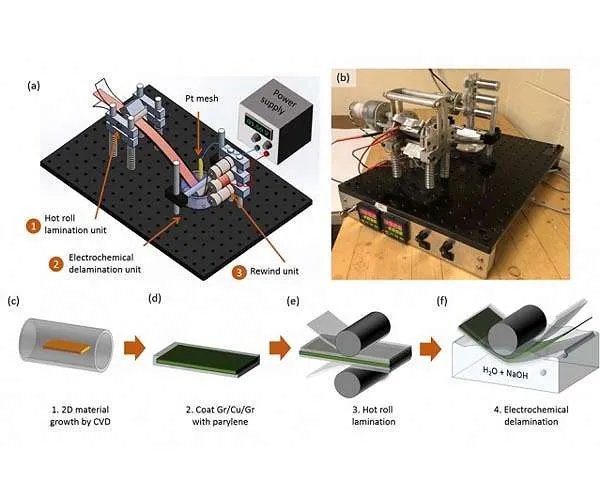

The new manufacturing process, which was created at MIT and needs to be fairly very easy to scale up for commercial production, entails an intermediate "barrier" layer of product that is key to the technique's success. The buffer allows the ultrathin graphene sheet, less than a nanometer (billionth of a meter) thick, to be quickly lifted off from its substratum, allowing for quick roll-to-roll manufacturing.

The process is described in a paper released the other day in Advanced Functional Materials, by MIT postdocs Giovanni Azzellino and Mahdi Tavakoli; teachers Jing Kong, Tomas Palacios, and also Markus Buehler; and five others at MIT.

Discovering a way to make slim, large-area, clear electrodes that are steady in outdoors has been a significant pursuit in thin-film electronic devices recently, for a variety of applications in optoelectronic tools - points that either emit light, like computer system and also smart device displays, or harvest it, like solar cells. Today's requirement for such applications is indium tin oxide (ITO), a product based on uncommon and also expensive chemical elements.

Many research study groups have actually worked with finding a replacement for ITO, concentrating on both natural as well as not natural prospect products. Graphene, a kind of pure carbon whose atoms are arranged in a flat hexagonal variety, has incredibly excellent electric as well as mechanical properties, yet it is vanishingly slim, physically adaptable, as well as made from a plentiful, cost-effective product.

Furthermore, it can be conveniently grown in the form of big sheets by chemical vapor deposition (CVD), using copper as a seed layer, as Kong's team has demonstrated. Nonetheless, for gadget applications, the trickiest component has actually been finding means to launch the CVD-grown graphene from its native copper substratum.

This launch, referred to as graphene transfer procedure, has a tendency to cause a web of splits, wrinkles, and also defects in the sheets, which interferes with the movie connection as well as a result significantly minimizes their electrical conductivity.

But with the new innovation, Azzellino says, "now we have the ability to accurately make large-area graphene sheets, move them onto whatever substratum we want, as well as the way we transfer them does not impact the electrical and also mechanical properties of the excellent graphene."

The trick is the barrier layer, made from a polymer material called parylene, that conforms at the atomic level to the graphene sheets on which it is deployed. Like graphene, parylene is generated by CVD, which simplifies the production process and scalability.

As a demonstration of this technology, the team made proof-of-concept solar cells, taking on a thin-film polymeric solar cell material, in addition to the newly created graphene layer for one of the cell's 2 electrodes, as well as a parylene layer that additionally acts as a tool substratum. They determined an optical passage near 90 percent for the graphene movie under visible light.

The prototyped graphene-based solar cell enhances by approximately 36 times the supplied power per weight, compared to ITO-based advanced tools. It also utilizes 1/200 the amount of product per unit location for the transparent electrode. And, there is a further fundamental benefit contrasted to ITO: "Graphene comes for almost free," Azzellino says.

" Ultra-lightweight graphene-based devices can lead the way to a brand-new generation of applications," he claims.

" So if you think about mobile gadgets, the power per weight comes to be a really essential figure of benefit. What happens if we could release a clear solar cell on your tablet that is able to power up the tablet itself?" Though some additional advancement would be needed, such applications ought to eventually be practical with this brand-new method, he claims.

The barrier material, parylene, is commonly used in the microelectronics sector, typically to encapsulate and also secure electronic devices. So the supply chains as well as equipment for making use of the material currently prevail, Azzellino says. Of the 3 existing kinds of parylene, the team's examinations revealed that a person of them, which consists of more chlorine atoms, was without a doubt the most efficient for this application.

The atomic proximity of chlorine-rich parylene to the underlying graphene as the layers are sandwiched together gives a more benefit, by supplying a kind of "doping" for graphene, finally offering a more dependable and also nondestructive technique for conductivity improvement of large-area graphene, unlike lots of others that have been evaluated as well as reported until now.

" The graphene and the parylene films are constantly in person," Azzellino says. "So generally, the doping activity is always there, and for that reason the benefit is permanent."

The study group also included Marek Hempel, Ang-Yu Lu, Francisco Martin-Martinez, Jiayuan Zhao and Jingjie Yeo, all at MIT. The work was supported by Eni SpA with the MIT Energy Initiative, the U.S. Army Research Office via the Institute for Soldier Nanotechnologies, and the Office of Naval Research.

Also read