Sound Waves Make Solar Cells Cheaper

- Discover how scientists are using a new process called acoustic spalling to reduce the cost of manufacturing III-V solar cells. This technique promises to create a cleaner, reusable surface, while maintaining cell efficiency. Research reveals that this technology could be commercially viable.

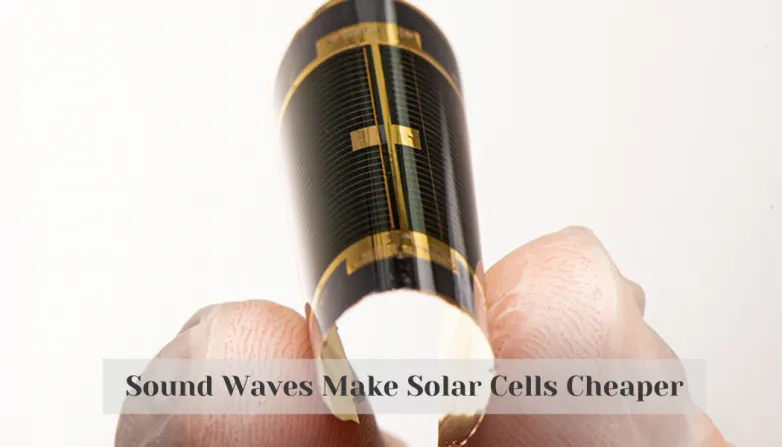

Scientists from the U.S. Department of Energy's National Renewable Energy Laboratory (NREL) and other institutions have developed a new process called acoustic spalling, which uses sound waves to reduce the cost of manufacturing III-V solar cells. This new process could make it possible to reuse the substrate on which the cells are grown, significantly reducing costs. The acoustic spalling process takes just seconds to create a controlled fracture within a Gallium Arsenide (GaAs) substrate, while leaving behind a new, contaminant-free surface that does not require polishing or other reparation. Research suggests that the efficiency of cells grown on previously spalled substrates is just as high as those grown on brand-new substrates. This technology is being commercialized by a company called Crystal Sonic, and further research is needed to determine how many times the substrate can be reused after acoustic spalling.

How Can Acoustic Spalling Reduce Costs for Manufacturing III-V Solar Cells?

- Acoustic spalling can reduce costs for manufacturing III-V solar cells by allowing for the reuse of the substrate on which the cells are grown.

- The process takes just seconds to create a controlled fracture within a Gallium Arsenide (GaAs) substrate, leaving a new, contaminant-free surface that does not require polishing or other reparation.

- Studies show that the efficiency of cells grown on previously spalled substrates is the same as those grown on brand-new substrates.

- This technology is being commercialized by a company called Crystal Sonic, and further research is needed to determine how many times the substrate can be reused without affecting efficiency.

- The reusable substrate could significantly reduce the cost of manufacturing III-V solar cells, making them more accessible to a wider range of consumers.

Also read