Solar Giants' Fates May Hinge on a Fight Over 28 Millimeters

- A battle over the best size for a key part utilized to harness the sun's energy may determine which company has the edge in a $200 billion industry.

Two Chinese solar titans are in a tussle over technology standards that hinges on a simple 28 millimeters, with the outcome readied to determine which company has an edge moving forward in the $200 billion industry.

The fighters are the world's biggest solar makers, matching industry leader Longi Green Energy Technology Co. against the world's second-biggest player Trina Solar Co. And also the battle entails boasting rights over the suitable size for wafers, the key component for making solar modules: Which is better, Longi's 182-millimeter variation, or Trina's 210-millimeter?

The competition is similar to that in between Plane and also Boeing in determining which aircraft is best for the globe's carriers. Yet the risks are probably higher when it concerns producing the powerful devices that transforms sunshine into electrical power, as countries established ambitious plans for increase renewable resource capacity.

Who obtains the benefit in the present battle stands to substantially accelerate a currently outstanding growth record. Longi's market cap has soared almost eight-fold to $63 billion because the end of 2018, while Trina's nearly quadrupled to $20 billion from its trading launching two years ago.

The wafer battle has actually been brewing for more than two years, as Longi looked for to press pause on a decade-long race to make solar panels bigger. The company has actually gone to the media and market forums to campaign for its choice, criticizing its opponent's version as too large to produce reliable panels.

" We do not see evident value in boosting the size of modules-- rather the threat has actually plainly risen," stated Li Shaotang, elderly product supervisor of Longi Global Sales & Advertising And Marketing Facility. "Unrestricted growth can lead the market the upside-down."

Trina, on the other hand, has actually defended its setting to proceed broadening panel sizes.

" Growing from small to big is the long solar wafer advancement background," claimed Zhang Yingbin, head of Trina's product technique as well as marketing. "It is the No. 1 pattern of the industry."

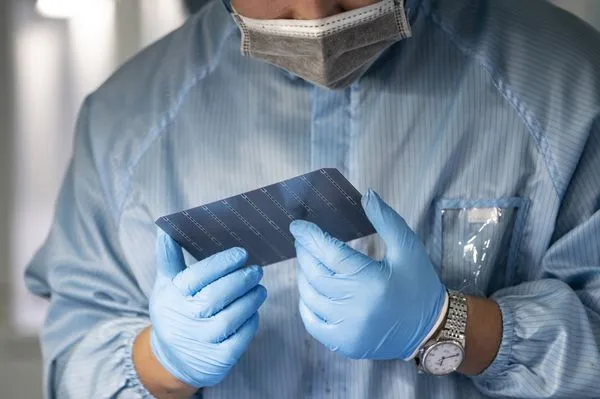

Wafers, the ultra-thin square piece of semiconductor, are the base system for solar manufacturing. They are wired right into solar cells of the very same size before being constructed right into panels. The bigger the wafer size, the less complicated to make larger modules, which could make electricity generation from solar less expensive.

In addition to being the world's largest photovoltaic panel manufacturer, Longi is also the top wafer manufacturer and also markets them to other firms also. Trina mainly relies on various other distributors for its wafers.

Simply 3 years ago, Longi remained in the position of defending bigger wafers as it attempted to push the sector to adopt its 166-millimeter variation as the brand-new standard over smaller sized predecessors. After that Trina leapfrogged it in 2020, introducing solar modules based upon 210-millimeter wafers. Longi responded with its 182-millimeter alternative, which has the included benefit of having the ability to be produced in several of Longi's existing factories after upgrades.

The two solar titans have actually ever since introduced more powerful panels based on the two wafer sizes, with Trina's largest module having 670 watts of capacity while Longi's biggest reaches 550 watts, much surpassing the maximum 400-watt designs over much of the past decade.

With both sides proactively campaigning for their standard, the 182 as well as 210 wafers incorporated have taken control of half of the market since 2021. The share is expected to reach 79% this year, according to PVInfolink.

Longi's Li said 182 is currently the most effective size for producing reliable and also effective photovoltaic panels. The business stated bigger panels made from 210 wafers are less resistant to extreme weather condition such as strong wind as well as hailstorm given the expanded area. The somewhat smaller sized solar modules based upon 182 wafers might match cargo containers much better, reducing transport expenses each time of expensive global delivery, Li claimed.

Trina defended the quality of its panels, saying they have actually been checked out by global verifiers and are running well in markets around the globe. Many thanks partly to Longi's criticisms, Trina boosted the caliber of safety glass for its modules, and also utilized broader frames to boost their resistance to external forces, Zhang claimed.

" What they assume can not be done does not indicate others can nor," he said. "Due to their difficulty, we have done comprehensive work."

The competition has split the market into two camps. Longi led 6 other firms, consisting of JA Solar Technology Co. and Jinko Solar Co., to develop a partnership backing its wafer standard. Trina signed up with hands with Longi's biggest rival in wafer manufacturing, Zhonghuan Semiconductor Co., and also loads of other supply-chain business to broaden production for large-capacity panels based upon 210 wafers.

Regardless of the split, a lot of makers in the meantime are likewise hedging their wagers, constructing brand-new production capacities that can switch over in between 182 as well as 210 wafers. Also Longi states its facilities can generate wafers as big as 230 millimeters, while Trina lately introduced a smaller sized rectangular wafer size with 182 as well as 210 as its edges.

" I don't believe that the future of solar is simply wafers growing and bigger, since you do begin to hit limitations on exactly how large the glass can be to stay tight adequate to hold up against high wind," claimed Jenny Chase, lead solar expert at BloombergNEF. "That claimed, there may be a couple of wafer sizes to go."

Also read