Sila: Leading Clean Transition With Silicon Anode-Lithium-ion Batteries

- Sila Nanotechnologies creates silicon anode for lithium-ion (Li-ion) batteries

- By 2028, the firm aims to increase the plant for manufacturing to power 2-10 million EVs/year

In our continuing series on battery tech and other firms to watch in the energy space, today we place the spotlight on Sila.

Sila is a battery tech company co-founded by a previous Tesla engineer Genetics Berdichevsky, additionally the CEO of Sila, Gleb Yushin, a Professor of Materials Science at Georgia Institute of Technology and an Editor-in-Chief for Materials Today, and also VP of Engineering at Sila Alex Jacobs (additionally a former Tesla worker). Before Sila, Berdichevsky was the seventh employee at Tesla Motors where he worked as Principal Engineer on the Roadster battery, leading the advancement of the globe's very first, risk-free, mass-produced, automotive lithium-ion battery system. Jacobs designed and also established battery packs at Tesla, including those utilized in the Roadster and Daimler's Smart Fortwo electric drive.

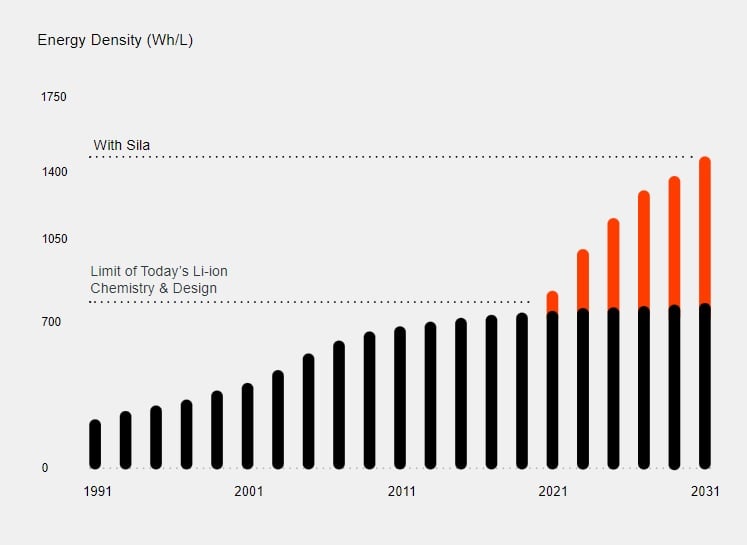

The firm is based in Alameda, California, United States. Sila Nanotechnologies is a next-generation battery products company charging ahead with its silicon anode for lithium-ion (Li-ion) batteries. The business is built on a solid platform of technology as well as advancements, with over a hundred patents, over 10 years, and also 55,000 versions that helped them establish a silicon-based anode that has to do with five times lighter as well as 2 times smaller sized than graphite-based anodes. Sila Nano products enable greater volumetric energy density, which suggests extra energy in each cell, as well as less cells in battery packs.

Sila wants to bring its material to smartwatches, phones, and various other devices in the future. The outcome will be slicker tools, longer battery life, or just space to cram in other helpful features that would certainly or else be reduced for size. Sila shipped the world's very first commercially available silicon anode for lithium-ion batteries in 2021. The American battery material manufacturer was likewise called on TIME's listing of Best Developments of 2022.

A Silicon Anode Battery

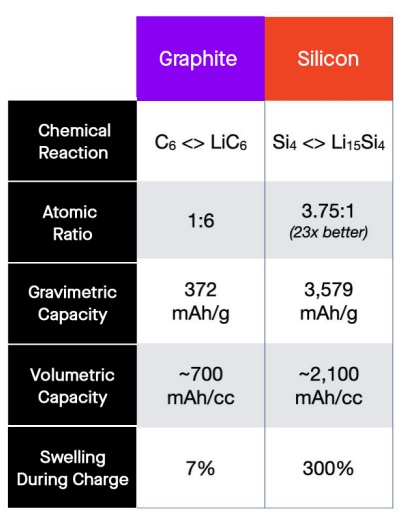

The firm had its breakthrough in silicon anode product at Georgia Tech. A bulk of Lithium-ion batteries today utilize graphite anodes. A problem with graphite is that 90% originates from China. Graphite's carbon dioxide emissions and also environmental impact are high. The firm declares that its next-gen silicon material shatters the energy ceiling set by graphite anode li-ion battery, allowing it to increase energy density by 20%-- 40 %.

With better energy thickness, large batteries get smaller sized, as well as little batteries obtain more effective, which is a game-changer for product developers and also cell producers. Sila claims that its batteries provide an energy thickness of over 800 Wh/L. Furthermore, Sila technology accommodates swell to protect cycle and also calendar life, charge performance, as well as safety. One more benefit of a silicon anode is it shops lithium in a much smaller quantity. The thinner Si anodes enable much quicker charging.

" In the next five to ten years, we will certainly see a$ 50 per kilowatt-hour( kWh) lithium-ion (Li-ion )battery cell that's capable of fast charging, 10,000+ cycles, over one-million miles, a 30-year calendar life, and also created with abundant resources located throughout the globe and reused. The demand for such a battery would get to unmatched degrees, "clarified the company in a white paper.

Scaling Next-Gen Battery

The firm operates from Alameda Plant with a production capacity that perseverance over 10 million tiny consumer tools. Sila's products drive battery performance enhancements in consumer electronics devices and also will power electric cars beginning with the Mercedes-Benz. The brand-new facility at Washington will certainly be supplying for Mercedes.

Sila Moses Lake Facility

The advanced silicon anode products will be manufactured using 100 per cent renewable energy in Sila's brand-new Moses Lake facility, in Washington, making Mercedes-Benz the manufacturing facility's first publicly revealed automobile consumer. By 2025, the anode manufacturing at the Washington facility will power 10 GWh of cells when used as a complete graphite replacement, or as much as 50 GWh of cells when utilized as a partial replacement. It is enough material to power batteries in approximately 100,000-500,000 premium EVs and also 500 million mobile phones annually. By 2028, the firm aims to increase the plant for production as much as 15x power. This is equivalent to 2-10 million EVs/year.

Funding

According to Crunchbase, Sila Nanotechnologies has elevated regarding$ 1B in financing over 7 rounds. Sila Nanotechnologies is moneyed by 15 capitalists with their latest financing elevated on Oct 19, 2022, a$ 100M Grant by the United States Department of Energy. Various other lead financiers include the similarity the American technology-focused investment manager Coatue ($ 590M), Canada Pension Plan Investment Board($ 45M), Mercedes-Benz Group AG($ 170M), as well as Sutter Hillside Ventures($ 70M), and National Science Foundation( $500K).

Also read

- Minnesota Approves 475 MW Solar, Storage Projects Expansion

- Green Genius Secures €36.7M for Major Lithuanian Solar Project

- Copenhagen Energy Taps Energrid to Build 132 MWh Danish Batteries

- Foresight Clinches UK’s Largest Two-Hour BESS with 400-MW HEIT Deal

- Photon Energy Sells Yadnarie Solar Project to AGL