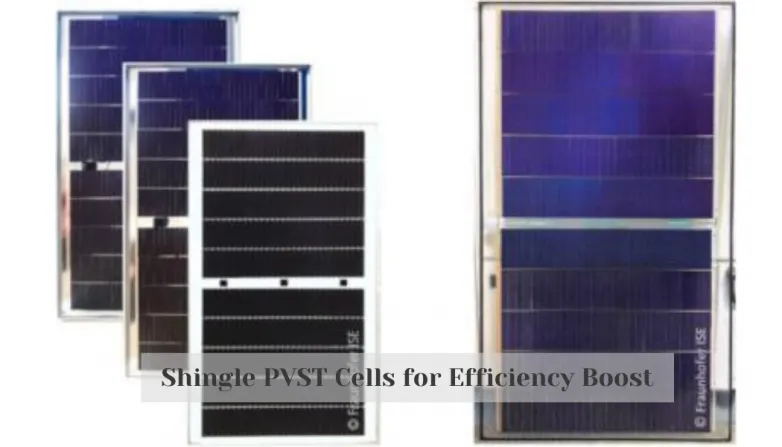

Shingle PVST Cells for Efficiency Boost

- Unlock the power of shingling for Perovskite-Silicon Tandem (PVST) cells with Fraunhofer ISE and Oxford PV's research. Increase module efficiency and reduce shadowing losses with their 1/6 cut PVST cells and low-temperature silver paste.

The scientists from Fraunhofer ISE and Oxford PV have examined shingling as an interconnection method for perovskite-silicon tandem (PVST) cells. The combination of PVST cells with shingling allows boosting the module efficiency due to the increase of the photoactive area. Shingled panels feature a busbar-free structure in which only a small proportion of cells are not exposed to sunlight. Reduced number of busbars can reduce shadowing losses. The researchers found that the 1/6 cut PVST cells with 25% initial shingle cell efficiency can achieve a module efficiency of 23.4%. Full-format modules with PVST cells produced efficiencies up to 22.8%. The team's work demonstrated the feasibility of the shingling approach and the successful metallization of PVST precursors with low-temperature silver paste by means of screen-printing.

What Are the Benefits of Shingling PVST Cells?

- Increased module efficiency due to increased photoactive area.

- Reduced shadowing losses with fewer busbars.

- 1/6 cut PVST cells with 25% initial shingle cell efficiency can achieve a module efficiency of 23.4%.

- Full-format modules with PVST cells produced efficiencies up to 22.8%.

- Low-temperature silver paste by means of screen-printing is used for metallization of PVST precursors.

- Reduced installation costs because of simpler busbar layout.

- Improved durability of PVST cells due to reduced thermal cycles.

- Reduced risk of corrosion and PID (Potential Induced Degradation).

Also read