Searching for cost-efficient techniques for III-V cell production

- Scientists in Canada have discovered a promising technique for the production of gallium-arsenide solar cells. Growing these cells straight onto a silicon substrate is an appealing strategy that could eliminate several of the innovation's inflated manufacturing expenses. And also by making that silicon permeable, scientists may have taken an action toward creating high-performance III-V solar cells at a substantially lower cost.

Gallium arsenide (GaAs) and also other III-V materials-- called for their collection in the periodic table-- are well known as high performance solar cell materials, holding most of total records for conversion effectiveness.

However their high production costs, typically in the series of thousands of dollars per watt, have actually thus far meant that such cells are limited to powering satellites, drones and various other specific niche areas where cell performance takes precedence over cost-per-watt of generation ability.

Reducing these manufacturing prices to a degree where mainstream solar applications can enjoy their efficiency possibility is an important subject, and scientists recently have recommended a variety of different techniques to this.

Expanding the GaAs layers on a silicon substratum is one appealing technique that would eliminate much more costly germanium from the mix, while enabling bigger location construction. Yet layers generated this way tend to have high degrees of problems, restricting their efficiency in a solar cell.

Researchers led by the Université de Sherbrooke in Canada explored whether making use of permeable silicon, instead of crystalline silicon (c-Si), might cause enhancements. Results of their examination are published in the journal Solar Energy Materials and Solar Cells, and also reveal considerable enhancements in fill factor as well as open circuit voltage when substituting crystalline for porous silicon in an otherwise the same process.

Nanoheteroepitaxy

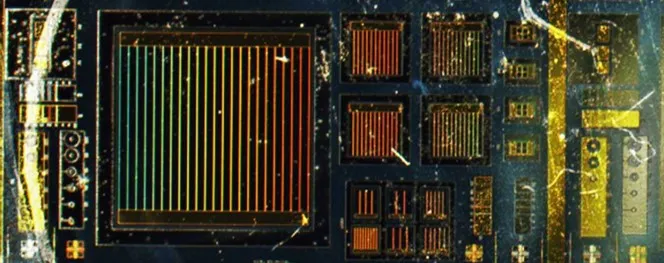

The team made use of a process called Nanoheteroepitaxy (NHE), where a semiconductor layer is grown on a formed substratum. The team utilized a two-step growth process, initial expanding a GaAs barrier layer to close over the pores in the silicon, and then depositing the major film at a temperature level of 565 levels Celsius.

A cell measuring 1 × 1 mm, expanded on permeable silicon showed a fill variable of 56%, compared to 41% for c-Si. The team put this down to less problems in the material, resulting in reduced recombination and also parasitic losses.

The group notes that the degree of issues in the cells it produced below would still need to be minimized to achieve rewarding cell performance, as well as suggests that further explores boosting the porosity of the silicon to make it much more versatile as well as better optimization of the barrier layer in the two-step development process deserve checking out to accomplish this.

Also read

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record

- Self-Assembling Molecule Breakthrough Brings Commercial Perovskite Solar Closer to Market

- Camphor Additives Boost Perovskite Solar Cell Efficiency

- NUS Sets Record With 26.4% Perovskite-Organic Solar Cell