Scientists realize large-area organic solar cells that are low-cost, flexible, and also reliable

- Organic solar cells (OSCs), that make use of organic materials to transform sunlight into electrical power, are an attractive candidate for future photovoltaics. This is because of numerous of their preferable features, such as their light weight, flexibility, pliability, and, most significantly, high power conversion efficiency (PCE). Such top qualities make them optimal for a vast array of applications.

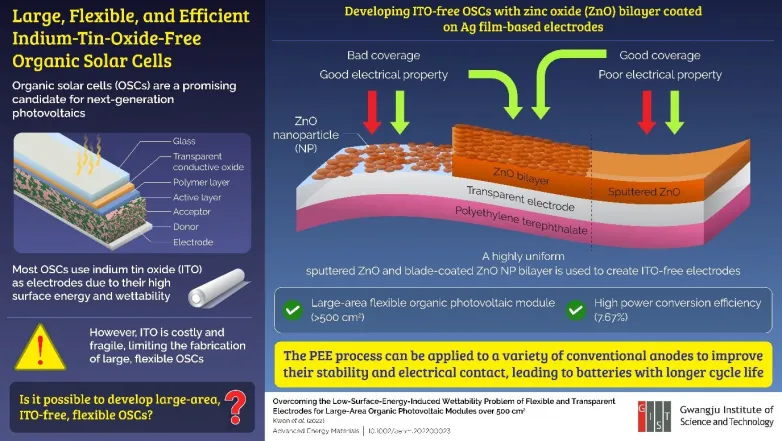

In spite of their massive commercialization capacity, nonetheless, there is a catch. The majority of OSCs are produced utilizing a technique called "rotate coating," which allows for high PCEs but creates inadequate scalability. Additionally, OSCs with flexible electrodes make use of indium tin oxide (ITO), that makes them pricey as well as too breakable for realizing large-area modules. Hence, if the commercial guarantee of OSCs is to be realized, they have to overcome their reliance on ITO.

This is where Dr. Hongkyu Kang as well as Prof. Kwanghee Lee from the Gwangju Institute of Scientific Research and Technology (GIST) in Korea can be found in. In their paper in Advanced Energy Materials they put forth a new method to produce OSCs using zinc oxide (ZnO) that overcame the issues of cost and also scalability without consisting of the PCE.

Particularly, this research study was the outcome of an industry-university cooperation, in which GIST established the original technology for the first time in Korea and moved it to MSWAY Co., Ltd., which had actually been entirely based on foreign imports as the domestic production of ITO-based electrodes was impracticable. With the new technology, it is expected that a value chain will be established for the commercialization of OSCs with building as well as equipment firms, reinforcing the value of industry-university joint research study.

The team utilized sputtered ZnO as well as a ZnO nanoparticle layer acquired with a "blade coating" technique to develop a uniform bilayer on an ultrathin silver film electrode. "The ultrathin silver film electrode with ZnO bilayer has the flexibility, wettability, and also high surface area energy of ITO however is not brittle or costly. This makes it much easier to use ZnO for producing organic solar cells and also creating a printing technology for large-area solar cell technology," states Dr. Kang.

The new ZnO bilayer-based OSCs showed an efficiency of 7.67% for a component area of 528 cm2, which makes it the most effective large-area OSC when contrasted to previous research. This was because of the decrease of "recombination" of charge service providers in OSCs by the crystalline ZnO nanoparticles that, consequently, enhanced their open-circuit voltage, i.e., PCE.

The development of these ITO-free OSCs with a large location and the very same flexibility as well as efficiency as that of ITO-based OSCs can be a video game changer for the future of solar cell technology. "Our approach opens doors to the commercial use of these OSCs, such as their combination right into building wall surfaces and also windows to realize self-reliant buildings," states Prof. Lee. Undoubtedly, the supremacy of large-area OSCs in regards to commercial possible and efficiency can usher in a new age of power generation and help us in the fight against climate modification.

Also read