Reordering the layers in solar-cell modules can aid improve efficiency

- A solar-cell module that mitigates cell-to-module losses has actually been established by KAUST researchers complying with a rethink of the module's optical design as well as how it must be stacked.

Research laboratories all over the world are functioning to regularly improve the efficiency of solar cells. However utilizing these gadgets in the real world stands for an extra challenge. For example, solar cells need to be incorporated into modules that can protect the delicate materials from severe environments. These modules can minimize the power conversion efficiency, hence losing the efficiency acquires so diligently won in the laboratory.

Lujia Xu, Stefaan De Wolf as well as their KAUST colleagues have actually created a more reliable solar-cell module with an improved optical design. The solar cells made use of by the group were made of a combination of 2 light-absorbing semiconductors: one silicon and the various other made from a perovskite product. Silicon is now a well-established product in solar cell manufacture. And also while perovskites are an arising material, including a slim layer in addition to the silicon has currently been revealed to enhance performance with an acceptable rise in price.

These supposed perovskite-- silicon tandem solar cells have previously exhibited efficiencies in optical-to-electrical power conversion as high as 30%. As well as academic modeling has actually shown it could go as high as 45%. However when the KAUST team put their tandem solar cells right into a module, they found that the efficiency dropped from 28.9% to 25.7%. Their module was made by sandwiching the solar cells in between two glass sheets, with the within filled with thermoplastic polyurethane to envelop the solar cells.

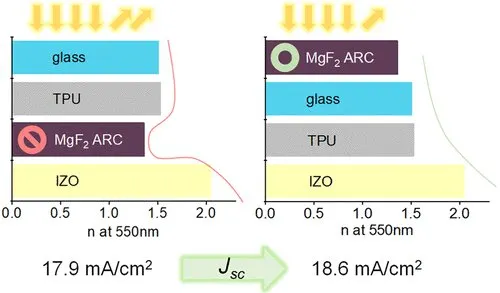

The group believe the reduction in efficiency is due to a refractive index mismatch after the introduction of glass and the polyurethane directly on solar cells without cell-to-module optimization, leading to raised reflection of the incoming light. Therefore the team decided to decrease this front reflection loss by an optical redesign of the module via refractive-index design.

By relocating a film of magnesium fluoride from the top of the cell to the top of the front glass, they minimized the refractive index mismatch, hence achieving efficient light in-coupling.

" This simple optimization efficiently makes it possible for the highest possible short circuit present thickness-- pertaining to the optimum current that can be drawn from the tool-- that is reported in the literary works for monolithic perovskite/silicon tandem solar modules, resulting in a power conversion efficiency rise from 25.7% to 26.2%," states Xu. "We now wish to explore exactly how various products and texturing the material surface area could reduce the current losses from cells to modules also further."

The study is released in ACS Energy Letters.

Also read