Reaction-dependent coffee-ring-regulating technique in spray-coating perovskite

- When droplets having non-volatile solutes completely dry on substrates, the fluid moves exterior by means of capillary force. Subsequently, the solutes are carried to the periphery of the droplets and also create "coffee rings" after drying out. This is known as the coffee ring result (CRE).

The CRE is typically observed during printing, and also it dramatically influences the harmony and also top quality of films, particularly in droplet-based dispersed deposition methods, such as spray-coating.

Just recently, spray-coating, which is a fully grown commercial technique, has been commonly utilized for the fabrication of perovskite solar cells (PSCs) owing to its high throughput, impressive compatibility with varied substrates, and good scalability. Nonetheless, the CRE-induced inhomogeneity of the splashed films causes poor tool reproducibility and also restricts the enhancement in gadget performance. The power conversion efficiencies (PCEs) of sprayed PSCs are still dramatically lower than those of their spin-coated counterparts. Therefore, CRE elimination is of substantial useful rate of interest for the development of spraying methods for PSCs.

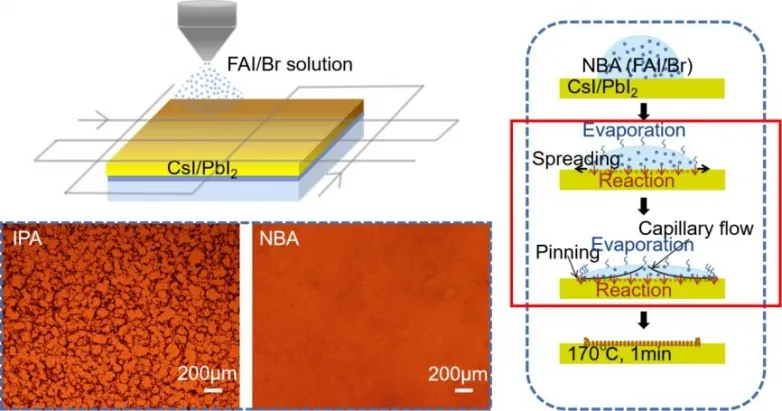

Just Recently, Prof. Peng and also colleagues at Wuhan University of Innovation reported a reaction-dependent coffee-ring-regulating method. In many research studies regarding CRE, the service does not react with the substrate. Nevertheless, in their research, the liquid droplets formamidinium iodide/formamidinium bromide (FAI/Br) reacted with the solid CsI/PbI2 films, which affected solute distribution. For that reason, the reaction process was regulated using solvent choice, and also it was established that solvents with sufficient drying out prices, such as n-butyl alcohol, can successfully subdue coffee ring development. On one hand, a suitable lengthy drying time advertised droplets spreading out and combining, as well as inevitably preferred the integrated wet films formation, which reduced the "rings" counts. Conversely, throughout dispersing, the reaction in between FAI/Br and also the CsI/PbI2 films impeded solute buildup at droplet periphery, leading to an uniform solute deposition. Lastly, thick, uniform, as well as highly consistent Cs0.19 FA0.81 PbI0.5 Br2.5 perovskite films were prepared. Owing to the premium quality of the perovskite films, the PCEs of the made PSCs reached 19.17%, which was amongst the highest PCEs of spray-coated PSCs reported to date.

In this research study, an efficient technique for controlling the CRE of spraying techniques to achieve high-performance PSCs was developed. Moreover, a new idea for the development of other printing modern technologies was recommended.

The research was published in the Journal of Energy Chemistry.

Also read

- UbiQD Secures Landmark Quantum Dot Deal with First Solar

- Astronergy Invests $53M in Tandem Solar Cell Project

- ARENA Unveils $39M Solar Innovation Funding Round

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record