Promoting the expansion of photovoltaics by cutting production times for high-efficiency solar cells by half

- When producing silicon solar cells, it is essential to have a high throughput. This lowers production prices as well as relieves supply traffic jams as more photovoltaics installments are being released in Germany and also worldwide.

Headed by the Fraunhofer Institute for Solar Energy Systems ISE, a consortium of plant suppliers, width business and research study institutions have come up with a proof of principle for an ingenious assembly line with a throughput of 15,000 to 20,000 wafers per hour to reply to this need. This stands for double the common throughput and is because of renovations to numerous private process steps.

This week's 8th World Conference on Photovoltaic Energy Conversion in Milan, Italy, will see the presentation of thorough results from the research study project.

" In 2021, 78% of all silicon solar cells were produced in China," discusses Dr.-Ing. Ralf Preu, Division Director of PV Production Technology at Fraunhofer ISE. "In order to release even more solar setups as promptly as possible and to make our supply chains more robust, Europe ought to re-establish its own production facilities for high-efficiency solar cells. By boosting throughput and also making production technology extra resource-efficient, we can cut expenses significantly and also unlock sustainability capacity that we will have the ability to take advantage of thanks to refine expertise as well as design excellence."

New concepts for silicon solar cell production

The consortium investigated every stage of the production of high-efficiency silicon solar cells to optimize the entire process. Numerous procedure steps required new growths. "For some procedures, well-known production operations required to be sped up, other procedures needed to be reinvented from scratch," discusses Dr. Florian Clement, project supervisor at Fraunhofer ISE. "Compared to the numbers we presently see, the production systems established within the scope of the project accomplish at the very least dual the throughput."

One of the new developments saw the researchers carry out new on-the-fly laser tools which consistently refines the wafers as they relocate at broadband under the laser scanner. For the metallization of solar cells, the consortium introduced rotary display printing instead of the existing typical procedure, flatbed screen printing.

Stack diffusion and also oxidization

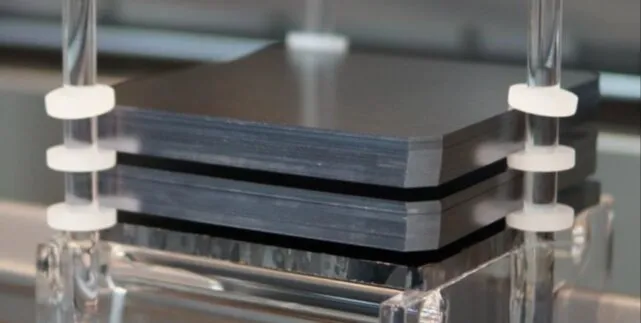

Solar cells require in a different way doped areas, for instance where silicon layer as well as metal contacts meet. The Fraunhofer ISE researchers integrated the diffusion procedure used in this context and also the thermal oxidization of the wafers right into one procedure step.

Wafers are no longer placed independently however stacked on top of each other to be processed in the heater. Therefore, the oxidization procedure creates the last doping profile as well as attains surface passivation at the same time boosting the throughput of the procedure by an element of 2.4.

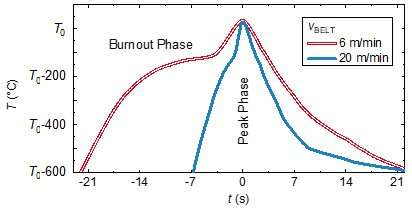

Faster inline heating system procedures

Following the electrode imprint on the solar cells, the contact of the electrodes to the silicon solar cell is based on both sides in inline furnaces. Standard furnaces would certainly have required a considerably bigger heating chamber to raise throughput at this stage.

Instead, the project consortium mounted a three times much faster belt speed in the heating system and also compared the top quality of the sintered solar cells with today's standard. They were able to dramatically raise throughput while not compromising the effectiveness of the solar cells.

Contactless testing and also evaluation of defects

For the characterization of the total solar cells, the consortium created two principles. A contactless approach and a technique utilizing gliding contacts were carried out to make it possible for future production lines to examination cells quicker.

This makes it possible to maintain a constant speed of 1.9 meters per second while determining the cells, with the group demonstrating great measurement precision for both concepts. A patent has been applied for the contactless technique.

Also read