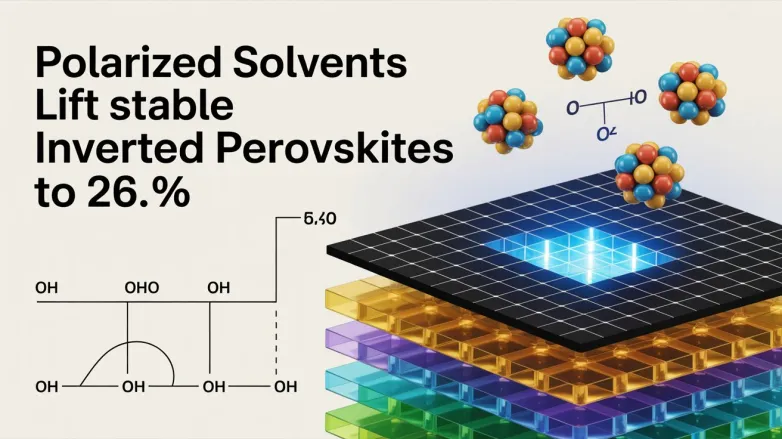

Polarized Solvents Lift Stable Inverted Perovskites to 26.4%

- Polarized-solvent tweak sets new 26.4% record for inverted perovskites. Fluorinated polymer tames crystallization, delivers pinhole-free films, 1,000-hour stability, and scalable manufacturing promise.

Chinese researchers reported a polarized-solvent method that stabilizes fragile intermediate phases during perovskite crystallization, delivering 26.4% efficiency in inverted perovskite solar cells—a record for this architecture—and markedly improved stability. By embedding a fluorinated polar polymer, poly(pentafluorostyrene), into the precursor ink, the team regulated solvent polarity and evaporation, yielding compact, pinhole‑free films. Devices retained 92% of initial efficiency after 1,000 hours under 1‑sun illumination.

Microscopy and in‑situ optics linked the stabilized intermediate to reduced defects, stronger photoluminescence, and narrower device variability. The polymer’s strong dipoles slow solvent release, promoting orderly grain growth and fewer deep traps—an approach that could translate to blade, slot‑die, and roll‑to‑roll manufacturing.

What does 26.4% inverted perovskite mean for scalable, bankable roll-to-roll production?

- Raises practical module-efficiency targets: 26.4% at cell level can translate to ~21–23% for R2R mini‑modules and ~19–21% for full‑width flexible modules after interconnect and area losses.

- Improves bankability narrative: inverted (p‑i‑n) stack’s low‑temperature, UV‑robust interfaces align with polymer substrates and long warranties, easing investor skepticism.

- Expands processing window: controlled crystallization that tolerates slower/managed solvent exit is compatible with blade, slot‑die, and R2R dryers with staged temperature/humidity zones.

- Boosts yield potential: denser, defect‑lean films reduce shunts and variability across web width, lifting first‑pass yield and narrowing power binning.

- Supports high‑speed coating: inks that remain stable over residence time enable >50–100 m/min web speeds with fewer drying defects and less edge‑beading.

- Lowers LCOE: higher module efficiency and yield cut area‑related BoS and labor; a 2–3 percentage‑point module‑efficiency gain can reduce LCOE by 5–10% depending on site.

- Enables flexible products: inverted stacks cure at ≤120–150°C, fitting PET/PI webs and metallized foils without warping, unlocking lightweight rooftop and BIPV markets.

- Eases tandem roadmaps: high‑performing p‑i‑n perovskites are the preferred top cells for perovskite‑on‑Si or CIGS tandems on R2R or hybrid lines.

- Simplifies encapsulation: lower ion‑migration and interface stress lessen requirements on barrier films and desiccants, improving reliability with standard flexible encapsulants.

- Aligns with in‑line QA: stronger PL and narrower device spread are compatible with web‑PL/EL, optical scatter, and sheet‑resistance metrology for closed‑loop control.

- Reduces anneal sensitivity: orderly grain growth cuts the need for aggressive thermal spikes, broadening dryer recipes and reducing energy consumption.

- Facilitates wider webs: more uniform nucleation supports 1–2 m web widths without center‑edge performance drift, improving throughput per tool.

- Shortens bankability path: record p‑i‑n stability signals are conducive to passing IEC 61215/61730, damp heat, thermal cycling, UV, and PID tests needed for project finance.

- Material supply considerations: additives and high‑purity salts must be available in drum/IBC volumes with consistent spec; early vendor qualification is key.

- EHS and regulatory: fluorinated additives may face PFAS scrutiny—suppliers must provide toxicology data, emissions controls, solvent recovery, and end‑of‑life plans.

- Cost model impact: polymer/additive cost is minor per m² if loadings are low; savings from yield/efficiency typically dominate.

- Process integration: ensure ink rheology (viscosity/surface tension) matches slot‑die heads, meniscus stability, and primer layers to maintain coat‑weight control.

- Interconnection compatibility: smooth, pinhole‑free films improve laser scribing (P1–P3) fidelity, reducing dead area and resistive losses.

- Field reliability: stabilized films should mitigate light‑soak drift and hysteresis, enabling tighter nameplate ratings and lower performance ratio uncertainty.

- Scale‑up milestones: demonstrate 30–100 m rolls with <3% PCE variability, pass 2,000 h ISOS‑L protocols, and secure third‑party audits to unlock banked commercial pilots.

Also read