Perovskite innovation-- past effectiveness documents

- Technical technology in PV is occurring in the context of severe rate competitors amongst solar producers, composes Karl Melkonyan, elderly expert for solar need at IHS Markit. This, he says, describes the concentrate on decreasing production expenses, raising performances, and also lowering losses in any way phases of the production procedure.

The typical effectiveness of industrial silicon components has actually enhanced in the last few years, in the series of 0.3-- 0.4 portion factors annually. These effectiveness gains have actually occurred in a really affordable atmosphere, because module rates have actually fallen by greater than 70% in the past 6 years alone.

Nonetheless, considering that mainstream innovations, such as p-type passivated emitter and also back cell (PERC), are gradually reaching their physical restrictions of conversion effectiveness, the market is progressively concentrated both on maximizing brand-new strategies and also advancements, as well as on using brand-new PV products and also modern technologies such as perovskites.

The conversion performance of perovskite solar cells has actually constantly boosted over the past 10 years. Taking into consideration that perovskite products for solar innovation remain in the onset of growth, the effectiveness renovations from 3.8% in 2009 to concerning 23% in 2018 are an incredible accomplishment. This effectiveness finding out contour is much steeper compared to any other arising PV innovation. Although the performances describe laboratory effectiveness and also not to mass-production industrial cells, they still suggest that perovskites can have a big influence on the solar market.

Perovskite manufacturing

Perovskite solar battery (PSC) innovation shares numerous resemblances with various other supposed third-generation solar cells. Especially in regards to cell layout as well as procedures, it is really near dye-sensitized solar cells (DSSC) and also natural solar cells (OSC, or OPV cells). Nevertheless, the fast development of PSCs can just partly be described by that resemblance, since each of the stated innovations is being established separately.

There is greater than one procedure to create PSC components. In its easiest technique, PSCs can be made by roll-to-roll layer, consisting of widely known innovations such as port die, spray covering, as well as ink-jet printing, or via dissipation. This procedure basically removes the requirement for wafer production as well as various other relevant procedures utilized in crystalline silicon (c-Si) cells.

One more benefit of PSC production is that perovskites can be made use of in both tandem-junction as well as single-junction innovations. The single-junction modern technology is the most basic kind, depending on a solitary layer of perovskite product, which provides the photoelectric result. Because type, the PSC can get to conversion performances of approximately 23%. To raise the performance to 27% as well as past, lots of research study institutes as well as start-ups are currently checking out making use of tandem cells, which are a sort of multijunction cell integrating the PSC as an added absorption layer on conventional c-Si cells, or on slim movies such as CIGS or CdTe components.

Barriers and also benefits

The benefits of perovskite modern technology are straightforward. The perovskite products are fairly economical contrasted to crystalline silicon, specifically monocrystalline p-type as well as n-type, because this modern technology does not need making use of polysilicon, silver paste, and also various other products made use of in common c-Si components. It can accomplish greater performances due to lengthy service provider diffusion size within the product, and also there is an opportunity to select the shade (absorption band) of the panel, as a result of the extensively tunable bandgap of the product. The PSCs can run with single-junction and also multijunction innovations (with c-Si as well as slim movie), and also appropriate in various applications and also sectors, such as constructing incorporated photovoltaics (BIPV), in addition to utility-scale solar plants.

Nevertheless, PSC innovation still calls for added enhancements in a number of vital locations, such as solid deterioration in the visibility of dampness, oxygen, UV light, and also heats. The poisoning of lead and also tin additionally requires to be dealt with, as those products are utilized throughout production, as well as can emerge throughout procedure as well as at end of life.

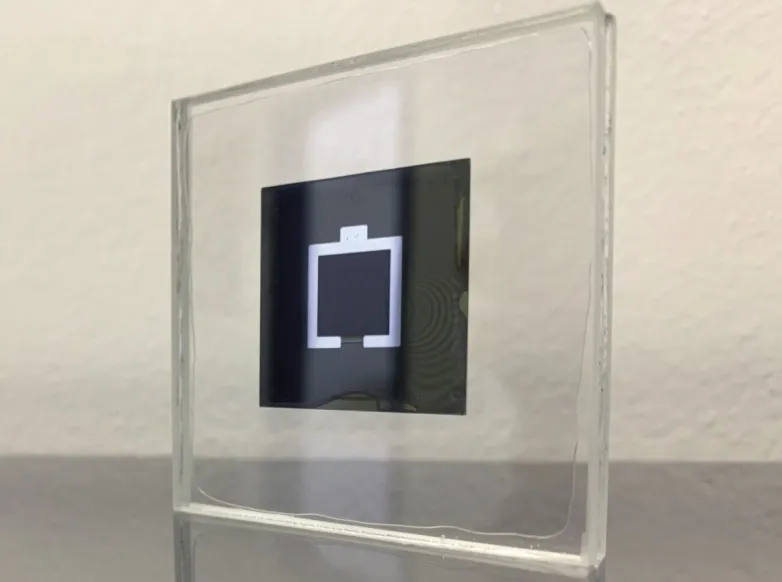

An additional crucial location of required enhancement is cell dimension. The stated document effectiveness of 18-- 23% that are frequently promoted current have actually been accomplished with really little cells, while cells that have a dimension suitable with real industrial usage still display a lot reduced effectiveness of 10-- 12%.

Altogether, the modern technology still requires to show that it prepares to meet all demands and also relocate from study cell examinations to business module manufacturing.

Applications, projections

PSCs possibly use much more benefits than c-Si cells in BIPV. PSC cells can be tinted or been available in various dimensions, and also the resultant components can be semi-transparent, along with bent and also flexible. Offered this, PSCs appear to be a better innovation for BIPV applications than c-Si cells, which can not or can just partly reproduce those variables. Because lots of BIPV projects are set up in respected structures, rate level of sensitivity stays less than in typical PV setups and also as a result they are extra positive to the very early fostering of PSCs. The application and also competition of PSC modern technologies in various other roof or ground applications still calls for additional growth of products, targeting a lot greater effectiveness in multijunction or tandem frameworks, and also a considerable manufacturing price decrease to get to business applications. In the current "Perovskite Solar Cells Report," released in January 2020, IHS Markit anticipates that the market will certainly await the automation as well as commercialization of perovskite cells (in solitary- as well as multijunction designs) within the following 3 to 5 years.

To day, there are just a couple of pilot lines generating PSCs and also just a handful of demo installments worldwide. The manufacturing ability of perovskite components is restricted to pilots and also presentation projects, as well as IHS Markit approximates that the overall mounted capability does not exceed 20-- 30 MW around the world. Nevertheless, many tools suppliers and also research study institutes are purchasing progressing the innovation as well as creating to boost conversion performances as well as boost existing obstacles with the instability and also deterioration of perovskite cells. Some firms have currently openly revealed that they will certainly begin business manufacturing in 2020. To show this, Saule Technologies, for instance, is currently increase its assembly line in Poland. Oxford PV is likewise dealing with devices provider Meyer Burger to move its tandem cell innovation to introduce industrial manufacturing this year.

Also read