Organic Solar Cell Innovation Improves Performance And Stability

- Scientists at the Gwangju Institute of Science and Technology have actually made a development utilizing water treatment for morphology control in organic solar cells.

- Morphology control is basically about making and putting really tiny particles in their functioning position.

- The exploration has actually improved the performance and stability of large-area organic solar cells.

Gwangju Institute of Science and Technology (GIST) scientists make use of a water treatment for morphology control in the construction of energetic layer thin films, improving the performance and stability of large-area organic solar cells.

Morphology control is basically regarding making and positioning very little bits in their working setting. Albeit rather a simplified description, as miniaturization becomes micro miniaturization and currently molecule, crystal and occasionally even atom positioning, the process engineering efforts are getting very difficult without a doubt. The efforts have been continuous for decades. These are basic troubles that in some cases just quit wonderful suggestions from reaching market.

Previously a lack of morphology control of the energetic layer made it challenging to establish organic solar cells (OSCs) with huge energetic areas.

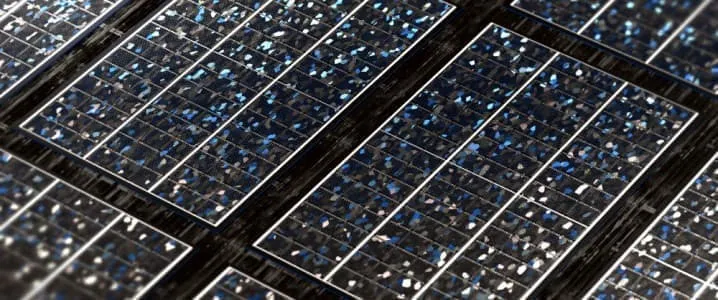

OSCs, which use organic polymers to transform sunlight right into power, have gotten considerable attention in current times for their preferable residential properties as next-generation energy resources. These consist of light-weight, flexibility, scalability, and a high power conversion efficiency (> 19%). Presently, a number of strategies exist for improving the performance and stability of OSCs. Nonetheless, a trouble that remains on is the trouble of controlling the morphology of the active layer in OSCs when scaling approximately huge locations. This makes it testing to obtain high-grade active layer thin films and, consequently, tweak the tool effectiveness.

In a recent research, a team of scientists from the Gwangju Institute of Science and Technology, Korea laid out to resolve this issue. In their job, released in Advanced Practical Products, they suggested an option that appears instead counterproductive at first glimpse: using water treatment to control the active layer morphology.

Professor Dong-Yu Kim, who headed the research study clarified, "Water is recognized to hinder the performance of organic electronic gadgets, because it stays in the 'catch states' of the organic product, obstructing the fee flow and degrading the gadget performance. Nevertheless, we figured that utilizing water rather than an organic solvent-based active solution as a tool of treatment method would enable needed physical modifications without triggering chemical reactions."

The scientists chose the polymers PTB7-Th and PM6 as benefactor products and PC61BM and EH-IDTBR and Y6 as acceptor materials for the active layer.

They discovered that generating a vortex to mix the contributor and acceptor products in the active solution might lead to a well-mixed energetic service, yet it was inadequate on its own. The energetic service was hydrophobic and, appropriately, the researchers chose to utilize deionized (DI) water and vortices to stir the solution.

They allow the donor and acceptor products sit in chlorobenzene (host active option) overnight, and after that included DI water in the service and stirred it, producing tiny vortices.

Because of the hydrophobic nature of the service, the water pushed on the benefactor and acceptor molecules, triggering them to dissolve even more carefully into the option. They then let the service remainder, which created the water to divide from the solution.

This water was then eliminated and the water-treated active remedy was utilized to prepare thin films of PTB7-Th: PC61BM (F, fullerene), PTB7-Th: EH-IDTBR (NF, fullerene), and PM6: Y6 (H-NF, high-efficiency non-fullerene).

The researchers then checked out the photovoltaic or pv performance of these thin films in a slot-die-coated inverted OSC arrangement and contrasted them with those for OSCs without water treatment.

Prof Kim kept in mind, "We observed that the water-treated energetic solution resulted in a more uniform active layer thin films, which showed higher power conversion effectiveness compared to those not treated with water. Furthermore, we produced large-area OSC modules with an energetic location of 10 cm2, which showed a conversion effectiveness as high as 11.92% for water-treated H-NF films."

Generally, this study offers a standard for developing large-scale, efficient OSCs utilizing an incredibly very easy, affordable, and eco-friendly approach, which can open doors to their understanding and commercialization.

Also read

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record

- Self-Assembling Molecule Breakthrough Brings Commercial Perovskite Solar Closer to Market

- Camphor Additives Boost Perovskite Solar Cell Efficiency

- NUS Sets Record With 26.4% Perovskite-Organic Solar Cell