New technique increases effectiveness, sustainability of large-scale perovskite solar cells

- A global group of researchers has actually shown a technique for generating perovskite photovoltaic products on an industrial scale, which will lower the expense and enhance the performance of mass-produced perovskite solar cells.

The strategy is inexpensive, simple, energy-efficient, and must pave the way for developing perovskite solar cells. Perovskite is of interest for solar cells due to the fact that it takes in light really efficiently. This permits the production of light-weight, flexible solar cells that can be included into a series of innovations, such as the windows of buildings or vehicles.

" In the laboratory, researchers create perovskite photovoltaic or pv products making use of a method called spin coating, which develops a thin film of perovskite on a substratum - but only on a little scale," claims Aram Amassian, co-corresponding author of a paper on the work as well as a teacher of products science and also engineering at North Carolina State University.

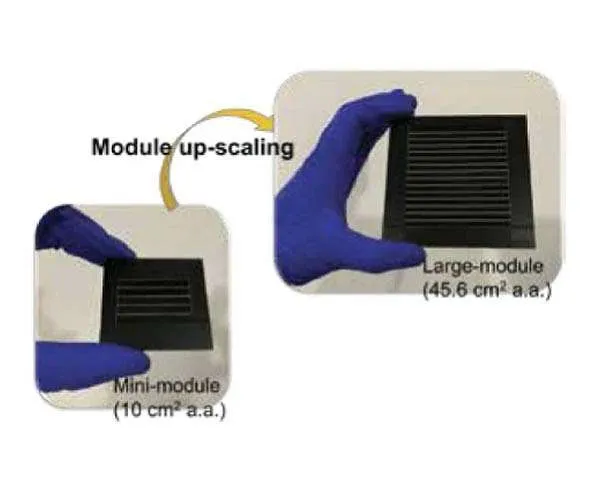

" We're speaking about example substrates that are only one or more centimeters square. Nevertheless, individuals really did not assume it was possible to scale spin-coating up for manufacturing, making use of substratums that are tens of centimeters square. Instead, individuals have actually chosen a range of other approaches. Yet these various other approaches generate perovskite photovoltaics that do not do in addition to the thin films made using spin coating and also needed significant research and development."

" What we have actually done here is show that you can produce perovskite photovoltaics on larger substratums making use of spin coating by designing a co-solvent dilution strategy," says Michael Gratzel, co-corresponding author of the paper and a professor at Ecole Polytechnique Federale de Lausanne. "Simply put, you can scale up production of photovoltaics and also maintain the superb efficiency of virtually any type of kind of perovskite thin film generated making use of spin coating."

Historically, people thought spin coating could not be made use of to generate perovskite photovoltaics on industrial-scale substratums in a material-efficient way due to the nature of both spin coating as well as perovskites.

Spin coating includes putting a liquid externally of a substrate and after that spinning the substrate, to make sure that the liquid product spreads across the surface. However, when perovskite is used using this method, the solvents that keep the perovskite in a liquid state don't evaporate promptly sufficient. This causes a lot of the perovskite to fly off the sides, implying a great deal of the perovskite material is thrown away. It also causes uneven density of the perovskite externally, in addition to some locations of the perovskite taking longer than others to dry. All of which is problematic from a manufacturing standpoint.

" Our strategy tackles this obstacle by presenting a co-solvent that permits the liquid perovskite to spread out evenly and also completely dry really rapidly as well as consistently," claims Hong Zhang of Ecole Polytechnique Federale de Lausanne, who is a co-lead author on the paper.

The brand-new strategy additionally considerably minimizes waste and also, by expansion, lowers harmful byproducts connected with making perovskite photovoltaics.

" The appeal of this method is that lots of industries already make use of spin coating innovations to create all sorts of products," states Aldo Di Carlo, co-corresponding author of the paper and a professor at the University of Rome Tor Vergata. "Our work shows that these existing innovations could be utilized to create perovskite solar cells. This could really speed up the manufacturing and implementation of perovskite photovoltaic panels and also cells."

Partners on the demo project are already using the brand-new method to generate modules that are tens of centimeters throughout with superb uniformity and also efficiency.

" My team is now concentrated on utilizing procedure automation and expert system to build on this work and also further boost efficiency, security and sustainability of perovskite photovoltaics," Amassian claims. "We're hoping to work with public and private sector interests on finding methods to execute this work and also increase the growth of perovskite solar cell innovations."

Also read