New process for kesterite solar cells with 10% efficiency

- German scientists have established a brand-new process for the development of a stage pure kesterite Cu2ZnSnSe4 (CZTSe), which they claim can improve the product homogeneity and also reduce the well-known concern of tin losses. The new method is based on piled essential and also alloyed forerunners with a Zn/Cu-Sn/Zn precursor framework.

German scientists have established a brand-new process for the development of a stage pure kesterite Cu2ZnSnSe4 (CZTSe), which they claim can improve the product homogeneity and also reduce the well-known concern of tin losses. The new method is based on piled essential and also alloyed forerunners with a Zn/Cu-Sn/Zn precursor framework.

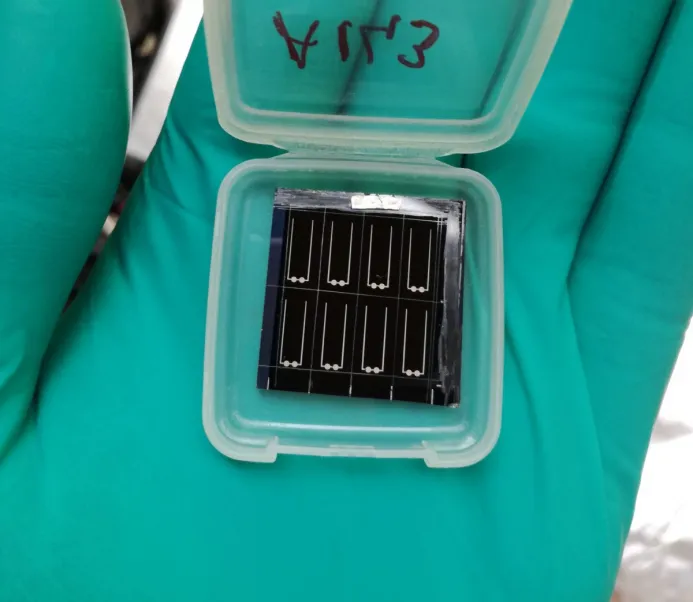

A group of German scientists has created a brand-new procedure for the formation of a stage pure kesterite Cu2ZnSnSe4 (CZTSe), to help with the advancement of a solar battery with an efficiency of more than 10%.

The researchers define the procedure in Reaction Pathway for Reliable Cu2ZnSnSe4 Solar Cells from Alloyed Cu-Sn Forerunner through a Cu‐Rich Selenization Stage, released in RRL Solar. The approach supplies a various way to control the make-up and also high quality of the produced product.

The typical procedure for expanding the kesterite is the selenization of stacked elemental metallic layers made of copper (Cu), tin (Sn) as well as zinc (Zn). This process, which additionally involves a response route containing binary selenides, should be done at annealing temperature levels of 500 C to 550 C, however that makes the response pathway prone to tin losses.

The proposed process, instead, is based upon stacked essential and alloyed precursors as well as a Zn/Cu-Sn/Zn precursor structure. According to the research group, piled elemental-alloy layers (SEAL) precursor containing Cu-- Sn alloy and elemental Zn layers use far better process control because of their benefits, such as enhanced product homogeneity as well as the suppression of the abovementioned tin losses.

" We show that starting with the SEAL forerunner and selenization without alloy segregation give a route of kesterite CZTSe formation without X-ray fluorescence obvious Sn loss," the researchers composed. "Consequently of the Cu‐rich starting structure and also bonding of Sn in the alloy structure, the development and also subsequent evaporation of SnSe2 − x stages in the reaction are dramatically decreased, preventing Sn loss from the layer throughout the selenization process."

The recommended procedure better shows the opportunity of an in-process structure shift in the sample from initially Cu-rich to finally Cu-poor. "This allows for the layout of a specified reaction and also make-up path throughout the process, which could be a novel strategy for getting to higher solar cell effectiveness, as understood for high-efficiency CIGSe solar battery handling," the scientists further explained.

Kesterite is just one of one of the most appealing light absorber material candidates for prospective use in lower-cost thin-film solar cells. Kesterites are consisted of typical aspects, such as copper, tin, zinc and also selenium and also, unlike copper indium gallium selenide (CIGARETTES) substances, no supply bottlenecks are anticipated in the future. The last, nonetheless, is currently able to provide cell performances close to 20%, while kesterites have actually so far attained effectiveness of just 12.6%.

In December, Estonian scientists announced the advancement of a brand-new monograin powder innovation made from microcrystals, which can develop identical connected mini kesterite solar batteries in a huge module. By replacing copper with silver in the absorber product, the researchers had the ability to attain a performance of 8.7%.

In August 2018, Australian scientists attained a 10% efficiency rate for a cell based on copper zinc tin sulfide, or sulfide kesterite. The globe document for such cells is 12.6%, attained by Japanese thin-film producer Solar Frontier in 2013.

In 2014, researchers from Helmholtz-Zentrum Berlin exposed that they were attempting to replace tin with germanium in the growth of kesterite solar cells.

Also read