New method might just print perovskite LEDs

- Microelectronics make use of numerous useful materials whose buildings make them appropriate for certain applications. For instance, transistors and also data storage devices are made from silicon, and also a lot of photovoltaic cells utilized for creating electricity from sunlight are additionally currently made of this semiconductor material.

On the other hand, compound semiconductors such as gallium nitride are used to produce light in optoelectronic aspects such as light-emitting diodes (LEDs). The manufacturing procedures additionally different for the various courses of products.

Hybrid perovskite products guarantee simplification - by organizing the natural as well as inorganic elements of semiconducting crystal in a details framework. "They can be used to make all kinds of microelectronic parts by modifying their composition", states Prof. Emil List-Kratochvil, head of a Joint Research Group at HZB as well as Humboldt-Universitat.

What's even more, processing perovskite crystals is somewhat basic. "They can be produced from a fluid option, so you can build the preferred part one layer at a time straight on the substratum", the physicist discusses.

First solar cells from an inkjet printer, currently light-emitting diodes as well

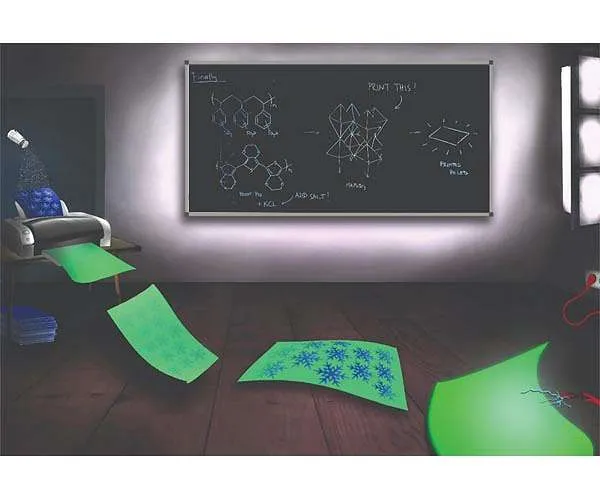

Scientists at HZB have currently received current years that solar cells can be printed from an option of semiconductor substances - and also are worldwide leaders in this innovation today. Now for the very first time, the joint team of HZB as well as HU Berlin has actually succeeded in creating practical light-emitting diodes in this way.

The research group made use of a steel halide perovskite for this function. This is a product that promises especially high performance in generating light - but on the other hand is tough to process.

" Until currently, it has actually not been possible to create these sort of semiconductor layers with adequate high quality from a fluid solution", claims List-Kratochvil. As an example, LEDs could be printed just from natural semiconductors, but these provide only moderate luminosity.

" The obstacle was just how to trigger the salt-like forerunner that we printed onto the substrate to crystallise swiftly and also equally by using some kind of an attractant or driver", clarifies the researcher. The team picked a seed crystal for this objective: a salt crystal that affixes itself to the substrate and also triggers development of a gridwork for the succeeding perovskite layers.

Substantially much better optical as well as digital features

This way, the researchers created printed LEDs that have much higher luminosity and also substantially better electrical properties than could be formerly accomplished making use of additive manufacturing processes. However, for List-Kratochvil, this success is just an intermediate step on the roadway to future mini- as well as optoelectronics that he believes will certainly be based solely on crossbreed perovskite semiconductors.

"The benefits offered by a single generally applicable course of materials and a single affordable and easy process for manufacturing any kind of kind of part are striking", states the scientist. He is for that reason planning to at some point make very important electronic components by doing this busy of HZB as well as HU Berlin.

List-Kratochvil is Professor of Hybrid Devices at the Humboldt-Universitat zu Berlin and also head of a Joint Lab founded in 2018 that is operated by HU along with HZB.

In addition, a team collectively headed by List-Kratochvil as well as HZB scientist Dr. Eva Unger is working in the Helmholtz Innovation Lab HySPRINT on the growth of covering and also printing processes - additionally known in technological lingo as "additive production" - for crossbreed perovskites. These are crystals having a perovskite framework that contain both not natural and natural components.

Also read