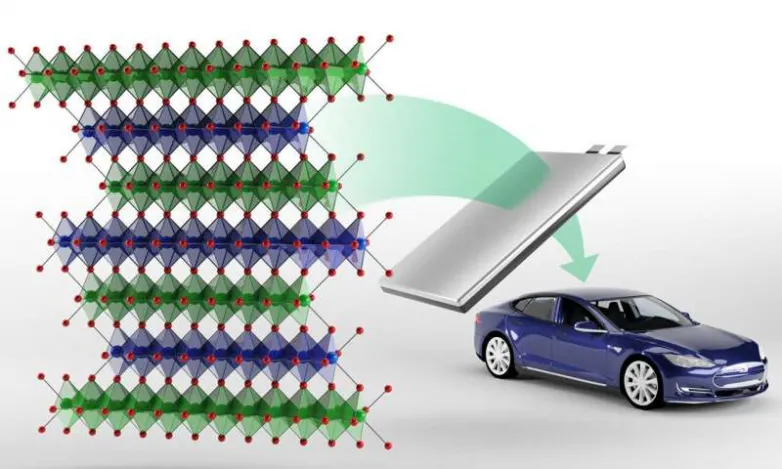

New class of cobalt-free cathodes can improve power thickness of next-gen lithium-ion batteries

- Oak Ridge National Laboratory researchers have created a brand-new family members of cathodes with the prospective to change the pricey cobalt-based cathodes generally located in today's lithium-ion batteries that power electrical lorries and customer electronics.

The brand-new course called NFA, which stands for nickel-, iron- and aluminum-based cathode, is a by-product of lithium nickelate and also can be used to make the positive electrode of a lithium-ion battery. These unique cathodes are made to be fast charging, energy dense, cost effective, and longer lasting.

With the rise in the production of mobile electronic devices and also electrical lorries throughout the globe, lithium-ion batteries remain in high need. According to Ilias Belharouak, ORNL's researcher leading the NFA research and development, more than 100 million electric cars are expected to be when traveling by 2030. Cobalt is a steel currently required for the cathode which makes up the considerable part of a lithium-ion battery's price.

Cobalt is rare as well as mostly extracted overseas, making it hard to get and create cathodes. As a result, finding an alternative material to cobalt that can be made cost effectively has actually ended up being a lithium-ion battery research study concern.

ORNL scientists evaluated the efficiency of the NFA course of cathodes as well as determined they are promising substitutes for cobalt-based cathodes, as defined in Advanced Materials and the Journal of Power Sources. Researchers utilized neutron diffraction, Mossbauer spectroscopy as well as various other sophisticated characterization techniques to check out NFA's atomic- and micro-structures as well as electrochemical properties.

" Our examinations into the billing and also discharging habits of NFA showed that these cathodes undertake comparable electrochemical reactions as cobalt-based cathodes and also deliver high enough certain capabilities to fulfill the battery energy thickness needs," said Belharouak.

Although research on the NFA course remains in the onset, Belharouak claimed that his group's initial results to date suggest that cobalt might not be required for next-generation lithium-ion batteries.

" We are establishing a cathode that has comparable or far better electrochemical features than cobalt-based cathodes while utilizing lower expense resources," he claimed.

Belharouak added that not only does NFA carry out along with cobalt-based cathodes, but the procedure to produce the NFA cathodes can be incorporated into existing international cathode production procedures.

" Lithium nickelate has actually long been researched as the product of option for making cathodes, yet it deals with inherent structural as well as electrochemical instabilities," he stated. "In our research, we changed some of the nickel with iron and light weight aluminum to improve the cathode's stability. Iron and aluminum are cost-effective, lasting as well as eco-friendly materials."

Future r & d on the NFA course will certainly consist of examining the products in large-format cells to verify the lab-scale outcomes and also further explore the viability of these cathodes for usage in electric automobiles.

Also read