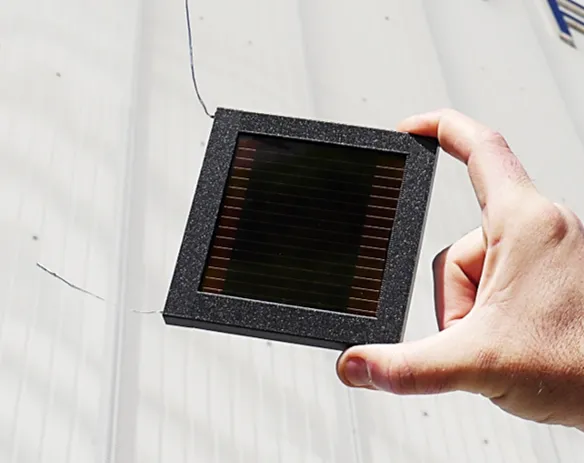

Mini perovskite solar module with 40 sq cm aperture area, 17% efficiency

- The 19.2%- efficient perovskite cells made use of in the module depend on an electron layer based on tin oxide that was transferred through chemical bath deposition. This technique, according to the gadget's creators, has made it possible to have a reasonably small decrease in efficiency from small cells to the 40cm2 module.

Scientists from the Institut Photovoltaïque d'Île-de-France (IPVF), in France, have actually created a mini perovskite solar module by using chemical bathroom deposition (CBD) for the deposition of the solar cell's electron layer, which is based upon tin oxide (SnO2).

Via CBD, a lot of substratums can be covered in a solitary keep up an appropriate chemical bath style. "CBD is a cost-effective deposition method that can create very uniform layers on huge areas at low temperatures," the researchers discussed. "CBD has actually previously been used at the commercial range to create cadmium sulfide (CdS) as well as zinc sulfide (ZnS) buffer layers in CIGS solar modules." The deposition process was performed for an hour and also the temperature level of the CBD activator was maintained steady at 70 degrees Celsius. "The desired SnO2 density was attained by repeating the CBD deposition process several times. Finally, the substrates were rinsed with water as well as annealed at 180 levels Celsius for one hr," the study team specified.

The solar cell was fabricated with a glass-coated substrate made from fluorine-doped tin oxide (FTO), the SnO2 layer, a movie made from a perovskite known as CsI/PbI that was transferred through slot-die coating, a spiro-OMeTAD hole-blocking layer, and a gold (Au) steel get in touch with. "This two-step deposition process, formerly created in our research laboratory, permits the deposition of consistent and pinhole-free perovskite layers," the academics stated, referring to the slot-die technique utilized. "During the procedure, an intermediate layer having CsI and also PbI2 is transferred by a very first slot-die coating action, then vacuum-treated to get rid of excess solvent and also afterwards transformed to perovskite [by] applying the natural cations service on top making use of a second slot-die coating step."

The module was constructed with 19.2%-efficient perovskite cells that were connected in series through laser ablation with P1, P2, and also P3 scribing actions. The champion panel, with an aperture area of 40cm2, achieved a power conversion efficiency of 17%, an open-circuit voltage of 17.61 V, a short-circuit current of 1.3 mA/cm2, as well as a fill element of 73.5%. "We believe that the reasonably small drop in efficiency from small cells to 40cm2 modules is because of the homogeneous deposition of the SnO2 layer and also of the perovskite layer, due to the use of [a] scalable technique," the researchers ended.

The mini perovskite module is introduced in the paper "Industrially Compatible Fabrication Process of Perovskite-Based Mini-Modules Coupling Sequential Slot-Die Coating as well as Chemical Bath Deposition", published in ACS Applied Materials & Interfaces.

Also read