Microstructure and issue engineering boosts performance of lithium-ion batteries

- A new North Carolina State University study, executed in collaboration with battery testing scientists at the U.S. Department of Energy's Oak Ridge National Laboratory, reveals that exceptionally short pulses from a high-powered laser can cause small flaws in lithium-ion battery products-- problems that can enhance battery performance.

The technique, called nanosecond pulsed laser annealing, lasts for only 100 milliseconds and also is created by the exact same type of laser made use of in modern eye surgical procedures. Researchers examined the technique on graphite, a product widely used in lithium-ion battery anodes, or positive electrodes. They evaluated the technique in batches of 10 pulses and 80 pulses as well as contrasted the differences in present capacity; power is calculated by multiplying voltage by existing.

Lithium-ion batteries are widely utilized in mobile digital devices as well as electrical automobiles. With further improvements, these batteries might have a major influence on transport and as storage devices for renewable resource resources like wind and also solar.

The study revealed a number of interesting outcomes, stated Jay Narayan, the John C. Follower Family Members Distinguished Chair in Materials Science at NC State and also corresponding writer of a paper explaining the job. Narayan pioneered using lasers to develop and manipulate issues in semiconductors in work spanning more than 4 decades. The job is released in the journal Carbon.

" Product defects can be a hassle, but if you craft them correctly you can make them a benefit," he said. "This technique unlocks, so to speak, for lithium ions, so it improves the present capacity. Graphite anodes consist of steps and grooves on the surface-- producing more actions resembles creating even more doors for lithium ions to enter and venture out, which is helpful.

" The technique additionally produces flaws called vacancies, which are missing atoms, which assists supply even more sites for lithium ions to come as well as go, which is related to the current capacity."

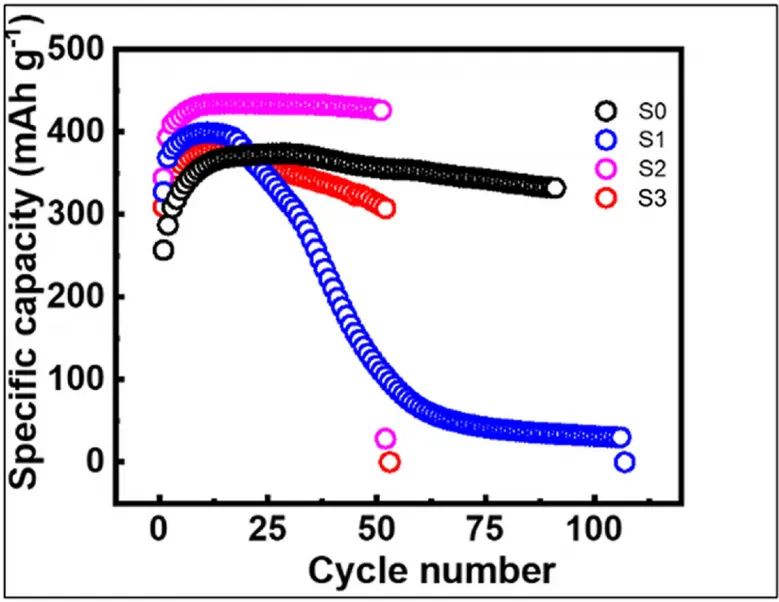

Current capacity enhanced by 20% when the optimal variety of pulses was made use of, which was closer to 10 than to 80 pulses.

The research study additionally showed, though, that as well much of a good point can be a poor thing, as a lot of problems in the graphite anodes can cause problems.

" Lithium ion has a positive fee, so if it records an electron it becomes lithium steel, as well as you do not want that," Narayan stated. "Lithium steel shoots out tiny cord dendrites from the graphite anode and can create a fire. So you intend to make sure that a lithium ion doesn't become a steel."

Narayan claimed that producers need to have the capability to use nanosecond pulse laser annealing when creating both anodes and also cathodes, the other electrodes consisted of in batteries.

" These high-powered lasers exist, as well as you can treat anodes and cathodes within a split second," Narayan said. "The cathodes or anodes are made on a sheet, that makes treatment relatively fast and also simple."

Narayan and colleagues at the University of Texas-Austin just recently published one more paper that made use of the very same laser technique on cathode products. Published in ACS Applied Materials and Interfaces, that research revealed laser treatment boosted cathode materials.

"Next off, we are attempting to eliminate the demand for utilizing much more costly products, such as cobalt in battery cathodes, in order to make higher power and longer-lasting batteries," Narayan said.

Roger Narayan, Distinguished Professor of Biomedical Design at NC State, co-authored the paper in Carbon in addition to first author Nayna Khosla, an NC State college student. Xiao-Guang Sun and M. Parans Paranthaman from Oak Ridge National Laboratory also co-authored the paper.

Also read

- Atmos Finalizes Funding for 100-MW Merredin Battery Project

- RPC, Greenfield Win Approval for Vale of Glamorgan Battery Storage

- Self-Assembling Molecule Breakthrough Brings Commercial Perovskite Solar Closer to Market

- Ignitis Unveils Ambitious 291-MW Battery Buildout Across Lithuanian Renewable Sites

- Renova Secures Financing for 30-MW Battery Project