Large location perovskite solar cell with copper steel call

- An Indian research group has actually built a perovskite cell that has a steel contact based upon copper, as opposed to expensive gold. The tool revealed almost the exact same effectiveness as a cell established with gold metallization but its security was much reduced. In order to conquer this problem, the researchers suggest making use of a metal get in touch with constructed from a thin layer of gold and a thicker, overlying copper layer.

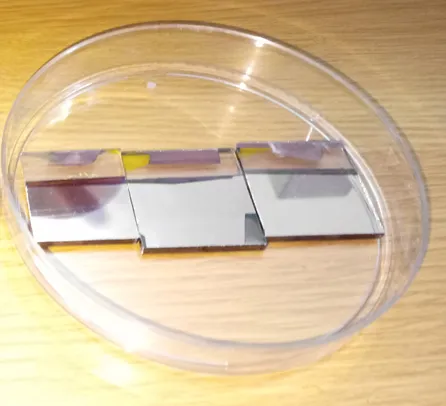

A team of scientists from the Indian Institute of Technology Bhilai has actually established a perovskite solar cell with an active area of 2cm2 and also a back contact electrode made from copper (Cu). "Efforts are on to boost stability with brand-new perovskite products and minimize costs at every feasible processing step," researcher Nikhil Chander informed pv magazine. "Our work has concentrated on reduction of costs by making use of copper contacts as opposed to gold."

The solar cell was produced using a two-step spin-coating strategy with a fluorine-doped tin oxide (FTO) substrate; a methylammonium lead iodide (MAPbI3) perovskite layer sandwiched in between a titanium oxide (TiO2) electron transport layer (ETL) as well as an opening transport layer (HTL) constructed from Spiro-OMeTA; and a copper conducting electrode. A comparable tool with a gold (Au) carrying out electrode was also built, as a recommendation cell. "Copper or gold call electrodes were deposited through a metal shadow mask by thermal evaporation to finish the cell manufacture process," the Indian team specified.

The scientists explained that the copper, silver and also aluminum utilized for metal calls usually bring about instability problems, as the diffusion of these metals with the Spiro-OMeOTAD or the perovskite layer has a chain reaction that might be detrimental for the cell's efficiency. "To name a few, affordable Cu has a relatively higher work function with decent security," the academics said. The work feature is the energy needed for a fragment ahead from the interior of a tool as well as break through the surface. This result needs to be taken into consideration when connections in between dissimilar steels in particular digital circuits are made.

The researchers developed a cell with an energetic area of 0.25 centimeters and also a bigger one with a location of 2cm2 and their performance was determined under conventional AM 1.5 G radiation by utilizing a 300-W xenon light as a light.

The 0.25 cm2 cell showed an effectiveness of 9.78%, an open-circuit voltage of 0.99 V, a short-circuit current density of 18.82 mA/cm2, and a fill aspect of 53%. For contrast, the same device with the Au steel contact attained an efficiency of 10.42%, an open-circuit voltage of 0.94 V, a short-circuit present thickness of 20.31 mA/cm2, and a fill variable of 54%. The gadget built with the Au contact electrode was also found to exhibit a reduced leak current thickness, which is helpful for the fill element.

When scaled up to the 2cm2 size, the cell showed a lower drop in the open-circuit voltage and also a substantial reduction in photocurrent. "The shunt resistance of both the Cu and also Au-based devices decreased when the dimension of the gadgets was raised," the research group emphasized. "It is an indication of raised shunting effects emerging because of scaling-up of the tool area."

The cell fabricated with copper metallization revealed an efficiency of 5.61%, and that based upon gold, 5.92%. These performances were examined over a seven-week duration as well as the gold-based device had the ability to keep around 74% of its initial efficiency while the copper-based cell retained just regarding 35% of the initial efficiency. "After 2 week under ambient conditions, the color of the perovskite film looks even more discolored," it described. "It is an indication of film degradation intoxicated of air as well as dampness." This deterioration was accountable for a strong reduction in photocurrent worths and the resulting fill variable decrease.

Also read