Japanese researchers test printing on perovskite

- Scientists from 3 Japanese colleges have actually established a procedure based upon inkjet printing they claim might decrease the expense of perovskite solar battery manufacturing. The team produced little cells with effectiveness as high as 13.19%, a number they declare is assuring sufficient to use the opportunity of scaling approximately business manufacturing.

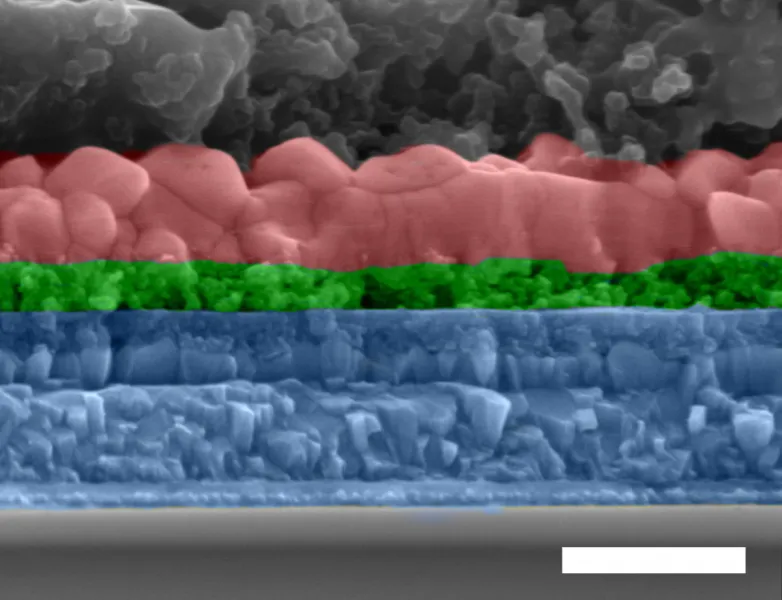

Researchers led by Japan's Kanazawa University have actually created a procedure for transferring a titanium dioxide electron transportation layer (ETL) onto a perovskite. The team declare the approach could be scaled as much as reduce prices for suppliers relocating in the direction of industrial perovskite cell production.

The ETL plays a crucial duty in lugging electrons from the perovskite right into the electrode as well as dividing from 'openings' to stop recombination losses. Titanium dioxide (TiO2) is currently frequently utilized to make the electron transportation layer. Nonetheless, the majority of procedures able to transfer a premium layer of it onto a perovskite need either heats or a vacuum cleaner, which relates to high operating expense.

" Fabricating high-grade, reproducible TiO2 CLs [portable layers] for the reliable efficiency of planar PSCs [perovskite solar batteries] through a scalable, economical and also controlled method stays a substantial difficulty," specified the scientists in their paper Oblique electrostatic inject-deposited TiO2 movie leads reliable perovskite solar batteries, released in Scientific Reports.

Checking out inkjet

To satisfy the obstacle of minimizing prices, the team relied on inkjet printing-- a procedure frequently made use of in the manufacturing of natural PV cells. By creating a maximized procedure for ETL layer deposition, the scientists had the ability to generate perovskite solar batteries with 13.19% effectiveness over an energetic surface of 0.09 centimeters ².

Favorably billed beads were splashed onto an adversely billed surface area. The team reported previous researches evaluating comparable procedures located gravity triggered TiO2 to create heaps-- causing thick, non-uniform layers. Nevertheless, by just splashing the forerunner at a 45-degree angle to the surface area, the team had the ability to boost harmony. Numerous the finish time enabled the Japanese group to manage the density of the ETL.

" The capacity to regulate the layer density and also accomplish an attire, reproducible layer at inexpensive-- without the demand for a vacuum cleaner-- offers a distinct bundle of benefits that has actually not been reported to day," claimed Md Shahiduzzaman, assistant teacher at Kanazawa University and also the paper's lead writer. "We really hope that these residential properties will certainly bring about readily appropriate as well as reliable scale-up that will certainly add to the drive in the direction of cleaner power worldwide."

Following actions

The team currently prepares to explore just how to scale up the procedure onto bigger locations, keeping in mind the 'solitary nozzle' technique considered the paper covers a size of just 5mm, which 'cross-talk' in between electrical areas around each nozzle can provide an obstacle to consistent printing with numerous nozzles. The researchers have actually assumed the positioning of a guard around each nozzle as a feasible service.

A refresher course to layer a range of substratums in a huge range, high-throughput setup is likewise prepared, as well as the team has actually recommended surface area design or important doping of the TiO2 layer might assist guarantee a great user interface in between the ETL and also the energetic perovskite, more boosting efficiency.

Also read

- Heliene, Premier Energies Partner for US Solar Cell Production

- Breakthrough: Stable High-Efficiency Perovskite/Silicon Tandem Solar Cells

- Enhancing PLED Performance Through Interfacial Fracture Study

- Enhancing Perovskite Thin-Film Interfaces for Solar Cells

- Waaree Energies Recognized in RETC PV Module Index