Inkjet printing manufacture leads method for functional perovskite solar cell manufacturing

- Scientists from Karlsruhe Institute of Technology have developed a brand-new manufacture strategy based on inkjet printing that might make it possible for quick, effective and also scalable production of perovskite solar cells.

Perovskite semiconductors are an extremely encouraging product for solar cells due to the fact that they absorb light and also convert it to power with much better efficiency and also possibly reduced production costs than the silicon utilized currently. However, more job is required to accomplish functional industrial-scale manufacturing of perovskite solar cells.

Helge Eggers, doctoral trainee in the research study group of Dr. Ulrich W. Paetzold from Karlsruhe Institute of Technology, will certainly offer the brand-new ink-jet printing approach at The Optical Society (OSA) 2020 Advanced Photonics Congress, an all-virtual conference held 13-16 July.

Inkjet printing is a scalable and product efficient deposition approach for solution-based products that enables to quickly readjust the printing patterns.

" Developing a well-working inkjet printing process for the manufacture of perovskite solar cells can not just allow inexpensive automation, yet would additionally provide to quickly change the published design based on electronic picture files opening the market for independently customized solar cells," claimed Eggers.

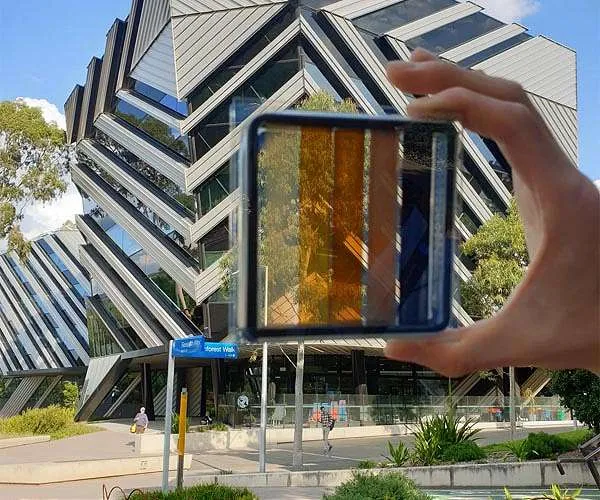

The study team shows that the new method can generate solar cells that convert light to power with performances that come close to those achieved with less-scalable manufacture approaches. Because their method could be used to print arbitrary patterns, it could likewise work for printing solar cells onto products used to turn skylights and constructing facades right into sources of power.

Optimized inkjet printing

The scientists started by utilizing their new technique to produce solar cells with an inkjet-printed perovskite absorber layer. Their essential accomplishments were the development of an enhanced ink and also fabrication procedure based on vacuum drying.

This procedure allows for a more effective formation pattern of the perovskite material with micrometer-large columnar grains. The solar cells showed a power conversion performance of more than 20 percent, which the authors state is the greatest conversion effectiveness reported for partly ink-jet printed perovskite solar cells. This result aids shut the performance void with state-of the-art spin-coated perovskite solar cells, which have an effectiveness around 25 percent.

They after that went one step better by producing perovskite solar cells with inkjet-printed absorber and extraction layers. These solar cells exhibited a power conversion effectiveness of greater than 17 percent. They also revealed that their maximized ink formula can develop millimeter-scale structures by printing detailed pictures of a few of the writers.

Although these results are an essential step towards the growth of scalable perovskite solar cells, there are still vital challenges to get over.

" At the minute we are still processing solar cells on laboratory scale. Upscaling inkjet-printed perovskite photovoltaics to big locations is a continuous effort," said Ulrich W. Paetzold, team leader of the Perovskite Taskforce at Karlsruhe Institute of Technology. "For this, we join our commercial partners in the field."

Inkjet-printed electrodes are under investigation by the team. In addition, the team is still enhancing the high quality and also reproducibility of the developed inkjet-printing procedure, given that even small changes in homogeneity of the printed movie can have a huge impact on the performance of the solar cell.

Also read