Gentle method allows for eco-friendly recycling of solar cells

- By utilizing a new method, rare-earth elements can be successfully recouped from thin-film solar cells. This is revealed by new research study from Chalmers University of Technology, Sweden. The method is additionally extra environmentally friendly than previous methods of recycling and also leads the way for more versatile and extremely effective solar cells.

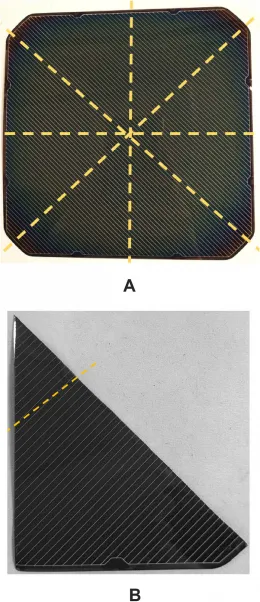

Today there are two mainstream sorts of solar cells. The most common is silicon-based and accounts for 90% of the market. The various other type is called thin-film solar cells which consequently makes use of 3 main sub-technologies, among which is referred to as CIGS (copper indium gallium selenide), and also consists of a layer of various metals, including indium as well as silver. Thin-film solar cells are by far the most reliable of today's readily available technologies. They can also be made flexible as well as versatile, which implies that they can be utilized in several locations.

The problem is that the need for indium and silver is high, as well as enhanced manufacturing is accompanied by a growing amount of production waste, which includes a mixture of valuable metals as well as hazardous substances. Being able to separate attractive metals from various other substances, for that reason, becomes incredibly valuable, both financially as well as ecologically, as they can be reused in new items.

" It is important to eliminate any kind of contamination and also recycle, so that the product becomes as clean as feasible once again. Previously, high warm and a huge amount of chemicals have been used to do well, which is an expensive process that is likewise not eco-friendly," says Ioanna Teknetzi, Ph.D. student at the Department of Chemistry and Chemical Engineering, who together with Burcak Ebin and also Stellan Holgersson released their new cause the journal Solar Energy Materials and also Solar Cells.

Now their research reveals that an extra environmentally friendly recycling procedure can have the very same end result.

" We considered both purity as well as environmentally friendly recycling problems and also studied exactly how to separate the metals in the thin-film solar cells in acidic remedies through a much 'kinder' way of using a method called seeping. We likewise have to utilize chemicals, however nowhere near as high as with previous leaching methods. To check the purity of the recovered indium and silver, we likewise measured the focus of possible pollutants as well as saw that optimization can lower these," says Teknetzi.

The researchers revealed that it is possible to recover 100% of the silver and regarding 85% of the indium. The process happens at room temperature without including heat.

" It takes one day, which is slightly longer than typical methods, yet with our method, it becomes much more cost-effective as well as much better for the environment. Our hopes are that our research can be used as a recommendation to enhance the recycling process and lead the way for making use of the method on a bigger scale in the future," states Ebin.

The method

- The film from the solar cell is analyzed with respect to product, chemical make-up, particle size and also thickness. The solar cell is placed in a container with an acid service at the desired temperature. Agitation is used to promote dissolution of metals in the acid service. This procedure is called leaching.

- Seeping efficiency and chemical reactions are assessed by analyzing examples taken at particular times during the leaching process. The different metals are seeped at various times. This suggests that the procedure can be quit in the past all the metals begin to dissolve, which subsequently contributes to attaining greater pureness.

- When the leaching is full, the preferred metals remain in the option in the form of ions and can be quickly cleansed to be recycled in the manufacture of new solar cells.

Also read