Epsilon Gets Certified as Anode Precursor Provider for Li-ion Batteries

- Epsilon gets preliminary order for its Anode precursor material and efficiently certifies as a vendor in the worldwide Li-ion battery supply chain

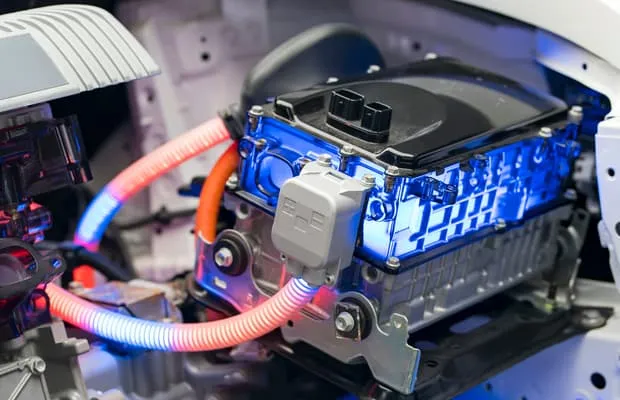

Epsilon Advanced Product, a leading residential supplier of innovative cell chemistry products as well as a subsidiary of Epsilon Carbon, has obtained a first order for its Anode precursor material from 2 top anode makers in Japan as well as China. Worldwide synthetic graphite has a 60 percent market share in the anode material space. With these positive results, Epsilon is efficiently certified as a vendor in the international Lithium-ion (Li-ion) battery supply chain.

This remains in line with Epsilon Carbon's more comprehensive strategy to come to be the globe's first up and down integrated and also sustainable anode material producer in the Lithium-ion battery supply chain with a plan to increase synthetic graphite capacity to 35,000 MT by 2025. The business is targeting sales quantities of 10,000 statistics tonnes of anode precursor material in FY22 with exports being a substantial contributor of the sales. The firm is additionally in the sophisticated phases of getting its product qualified with future cell production facilities in US as well as Europe.

Vikram Handa, Taking Care Of Director of Epsilon Carbon stated "Technical efficiency anode makers has actually shown that Epsilon material is extremely fit to sustain cell-makers in establishing longer array & fast billing batteries. This has been also been valued by the Battery Electronic Automobile (BEV) segment. Anode production is an important part of the battery supply chain. Epsilon Carbon with our sustained backwards assimilation of resources is finest put to support boost this worth addition for Indian-based battery/ cell suppliers while continuing to service our Worldwide customers' demand."

With the growing approval of electrical lorries, the Li-ion battery is most likely to control over the following years. Numerous nations have actually announced strategies to set-up battery making Giga factories to support their wheelchair and power storage requirements of 2600 GWh by 2030.

Similarly, under the Aatmanirbhar Bharat initiative, the central government has come-up with the PLI system for 10 sectors including Advanced Cell Chemistry battery to help with as well as advertise indigenous supply chain production abilities. Via this system at-least, 5 Giga manufacturing facilities (10 GWh each) are anticipated to come-up quickly with each manufacturing facility drawing in an investment of USD 1 billion. Under this plan, there is a total cash money aid of Rs ~ 34000 crore prepared over the following 10 years.

The company has actually disclosed that cell suppliers anticipating set-up their center under the PLI plan are coming close to Epsilon to protect their raw material needs. Epsilon being a 100 percent aboriginal manufacturer of anode material, gives them a competitive advantage in complying with localisation standards to make use subsidies. The firm's production leadership in graphite anodes will make India self-sufficient as a vital raw material for LiB cells. With a capacity of 35000 lots of artificial graphite, Epsilon would be able to sustain 35 GWh of cell manufacturing.

Also read