Discovering key to affordable, rapid manufacturing of solid-state batteries for EVs

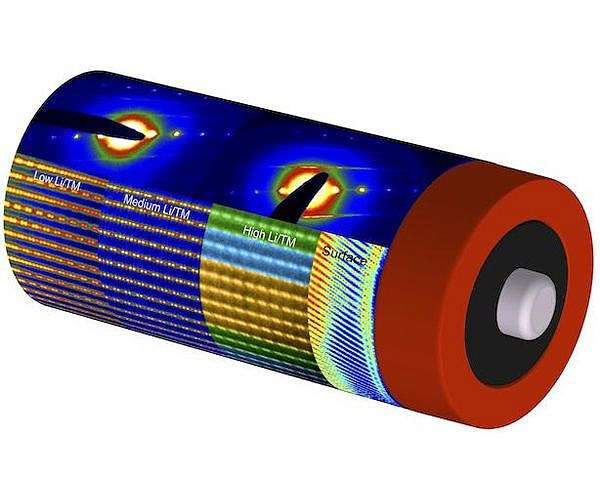

- A brand-new manufacture method can allow solid-state auto lithium-ion batteries to take on nonflammable ceramic electrolytes utilizing the very same production procedures as in batteries made with conventional liquid electrolytes.

The melt-infiltration technology created by products science scientists at the Georgia Institute of Technology utilizes electrolyte products that can be penetrated right into permeable yet largely jam-packed, thermally stable electrodes.

The one-step process creates high-density compounds based upon pressure-less, capillary-driven seepage of a molten strong electrolyte right into porous bodies, including multilayered electrode-separator stacks.

" While the melting point of standard strong state electrolytes can range from 700 degrees Celsius to over 1,000 degrees Celsius, we run at a much reduced temperature range, depending upon the electrolyte composition, about from 200 to 300 levels Celsius," discussed Gleb Yushin, a teacher in the Institution of Materials Scientific Research as well as Design at Georgia Tech. "At these lower temperature levels, manufacture is much faster and easier. Materials at reduced temperatures don't respond. The basic electrode assemblies, including the polymer binder or glue, can be secure in these problems."

The brand-new strategy, to be reported March 8 in the journal Nature Materials, could enable huge automotive Li-ion batteries to be made much safer with 100% solid-state nonflammable ceramic as opposed to liquid electrolytes making use of the exact same production procedures of traditional liquid electrolyte battery manufacturing.

The patent-pending production technology simulates low-priced construction of industrial Li-ion cells with fluid electrolytes, yet instead uses strong state electrolytes with reduced melting points that are melted and also infiltrated right into thick electrodes. Because of this, high-grade multi-layered cells of any type of size or shape could be rapidly manufactured at range utilizing tried and tested tools and processes established and enhanced over the last three decades for Li-ion.

" Melt-infiltration technology is the essential development. The cycle life and also security of Li-ion batteries depend strongly on the operating conditions, particularly temperature," Georgia Tech college student Yiran Xiao discussed.

" If batteries are overheated for an extended duration, they generally begin to weaken prematurely, and also overheated batteries may catch on fire. That has actually triggered almost all electrical vehicles (EV) to include advanced as well as instead expensive cooling systems." On the other hand, solid-state batteries may only need heaters, which are dramatically cheaper than cooling down systems.

Yushin as well as Xiao are encouraged by the possibility of this production procedure to enable battery makers to create lighter, safer, as well as extra energy-dense batteries.

" The established melt-infiltration technology is compatible with a broad range of product chemistries, consisting of supposed conversion-type electrodes. Such products have actually been shown to enhance automobile cell power thickness by over 20% currently and by more than 100% in the future," claimed co-author and Georgia Tech study scientist Kostiantyn Turcheniuk, noting that greater thickness cells support longer driving ranges. The cells require high-capacity electrodes for that performance jump.

Georgia Tech's technique is not yet commercially all set, however Yushin anticipates that if a considerable part of the future EV market accepts solid-state batteries, "This would probably be the only way to go," because it will certainly enable manufacturers to utilize their existing production centers as well as facilities.

" That's why we focused on this project - it was just one of one of the most readily practical locations of innovation for our lab to pursue," he said.

Battery cell rates struck $100 per kilowatt hour for the first time in 2020. According to Yushin, they will certainly need to go down below $70 per kilowatt hr before the customer EV market can fully open up. Battery advancement is important to that occurring.

The Materials Science lab team presently is focused on creating various other electrolytes that will certainly have lower melting points and higher conductivities making use of the same method proven in the lab.

Yushin visualizes this research group's manufacturing development opening the floodgates to extra innovation in this field.

" A lot of exceptionally smart researchers are concentrated on resolving very challenging scientific issues, while totally neglecting economic as well as technological functionality. They are studying and optimizing really high-temperature electrolytes that are not only drastically much more costly to use in cells yet are likewise approximately five times heavier compared to liquid electrolytes," he clarified. "My objective is to push the research study area to look outside that chemical box."

Also read

- Solar Developers Urge Biden to Boost Domestic Manufacturing

- Revolutionary CFS Technique for Rapid Perovskite Solar Cells

- Clearway Energizes Solar-Storage Mega-Complex in California

- Optimizing Guest Components for High-Efficiency Solar Cells

- Infinigen Expands Solar Project with 15-MW BESS in Puerto Rico