Construction of perovskite solar cells with just a piece of paper? A brand-new technique informs you exactly how

- Perovskite semiconductor solar cells are a very interesting solar innovation possessing comparable effectiveness to silicon but cast or published in slim films through liquid inks. A brand-new approach that uses a straightforward sheet of paper to deposit the perovskite films without any pricey devices has actually been established by a group from Tor Vergata University as well as College of Zanjan.

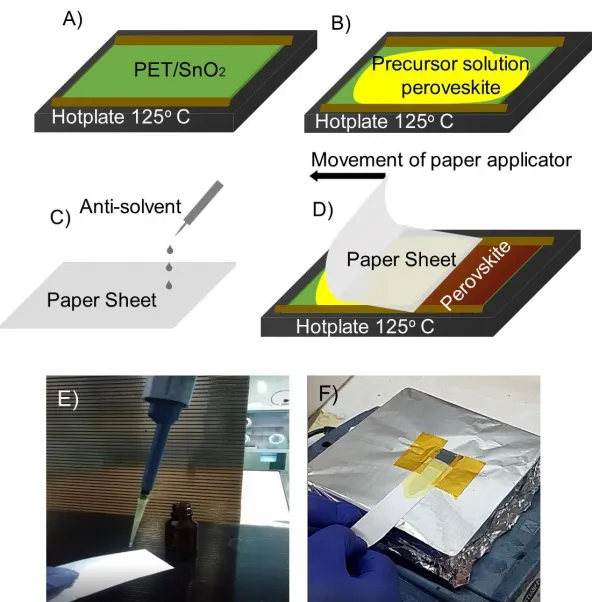

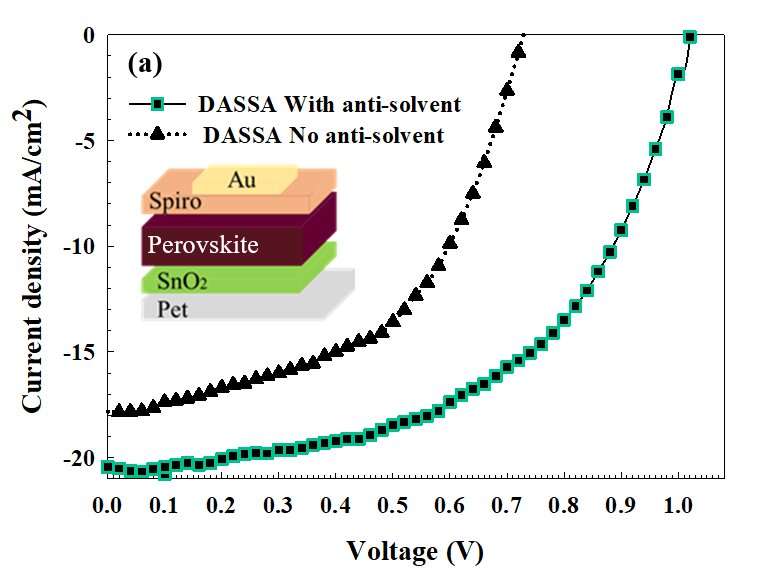

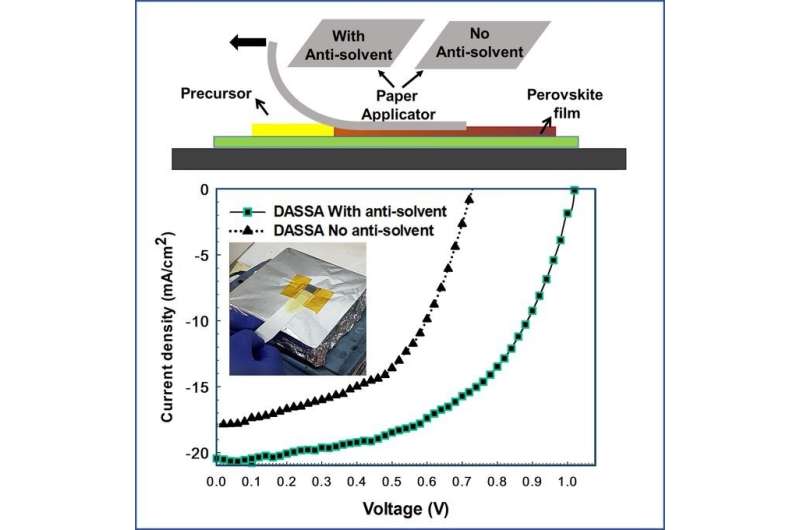

The technique to achieve high performance with this extremely cheap method is to soak the paper applicator in anti-solvent which practically doubles efficiencies compared to when using it completely dry, reaching 11% on flexible plastic substratums. Paper, compared to various other soft applicators, has the appropriate porosity as well as level of smoothness for deposition of excellent quality perovskite films.

Perovskite semiconductor solar cells are a really exciting photovoltaic or pv modern technology because they have comparable power conversion performances to those based upon conventional silicon but can be cast in slim films through forerunner inks providing benefits in production. A lot of perovskite films in labs all over the world are transferred via spin coating which ensures high control of film thickness as well as morphology. Nonetheless, a lot of the ink is removed during deposition as well as is thrown away. There have actually been efforts to create coating strategies for deposition over big areas. The most efficient solar cells produced by means of spin coating include including decreases of anti-solvent (i.e., a liquid with differing residential or commercial properties to those made use of in the perovskite forerunner inks) throughout spinning which improves the morphological quality of the perovskite semiconductor films. This approach is very hard to execute when using large location coating techniques, however, where the careful design of the drying out procedures entail heaters or gas moves to control the morphology of the perovskite film.

A global group of researchers from Italy and Iran has released an entirely brand-new method that uses a simple sheet of paper to transfer the perovskite films without a spin coater or other large location techniques such as slot-die coating or blade coating. Results of their project have been published in iScience, the open gain access to interdisciplinary journal from Cell Press, highlighting the dishes that are called for to attain efficient solar cells with this technique.

"When I joined CHOSE laboratories in Rome for my internship, I serendipitously noticed that leaving a piece of cleansing paper soaked in solvent over a damp perovskite forerunner film, it transformed brown developing into what resembled a rather appealing perovskite semiconductor film. My manager in Rome, Prof. Brown, suggested I established a coating method based upon this discovery during my time there" described Nazila Zarabinia, initial writer of the work. "We dealt with trying different soft applicators: the one that function best was paper possessing the most beneficial homes of porosity and also level of smoothness" she added. The highest effectiveness of a flexible cell fabricated with this Deposition through Anti-Solvent-Soaked Applicator method (called DASSA) was 11%. The researchers believe this is a satisfying performance, especially for flexible solar cells on plastic pet dog substrates, and also making use of an entirely hand-operated treatment. The equivalent effectiveness accomplished with spin coating gadgets with the anti-solvent technique was 14.9 % so there is extent for additional enhancement. In the manuscript, the writers propose an automatic treatment for more future optimization.

"We believe this easy technique will interest all those labs establishing a line in perovskite research study that have actually not been able (for money or time) to get pricey deposition devices (a bit like hands-on blade coating of titania films which was widely utilized to go into the area in the days of color sensitized solar cells) considering that it makes it possible for the deposition of the perovskite film extremely inexpensively. It can also be of particular passion to teams establishing automated printing strategies by using the anti-solvent, out the perovskite film customarily, but on the applicator rather. Additionally, it will certainly interest undertaking to expand this approach additionally to the transport layers for full cell manufacturing," commented Thomas M. Brown, corresponding writer of the work.

The scientists reveal that saturating the paper used as an applicator in an anti-solvent rises the power conversion efficiency of solar cells by 82% compared to the solar cells where the application of the perovskite film was performed with a sheet of completely dry paper.

Also read