Boost Perovskite Efficiency: Reduce Defects

- Researchers propose strategy to reduce defects and improve performance of inverted perovskite solar cells. The team achieved an efficiency of 25.1% and maintained 97.4% and 98.2% of their initial power conversion after 1,800 and 1,000 hours. Adaptable for improved efficiency and stability of other perovskite materials.

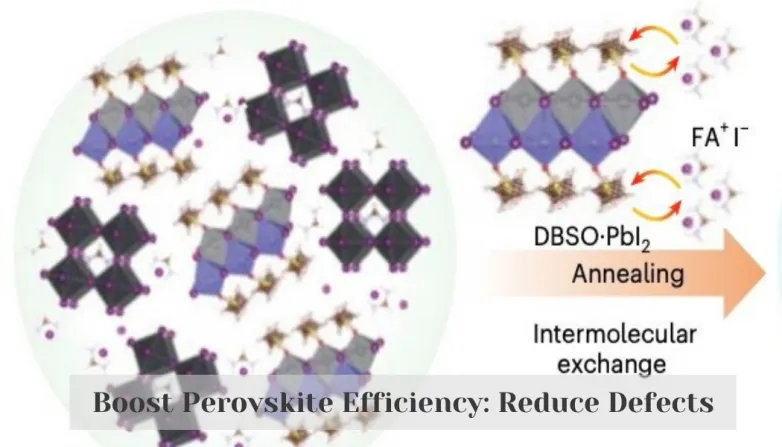

Researchers at Huazhong University of Science and Technology and other institutes in China have proposed a strategy to reduce defects in inverted perovskite solar cells (PSCs) and improve their performance. In particular, they focused on PSCs made with methylammonium- and bromide-free formamidinium lead triiodide (FAPbI3). To improve the performance of these cells, the researchers added a compound, called dibutyl sulfoxide (DBSO), to the bulk material to reduce its defects. They also treated the surface of the perovskite film with trifluorocarbon-modified phenethylammonium iodide (2CF3-PEAI) to optimize the energy levels and protect the film against moisture. The team found that the solar cells they developed performed remarkably well, reaching an efficiency of 25.1% and maintaining 97.4% and 98.2% of their initial power conversion efficiency after operating for 1,800 hours and 1,000 hours under specific conditions, respectively. This strategy could potentially be adapted by other teams to engineer more efficient and stable inverted PSCs, and to reduce defects in other perovskite materials.

How Can Defects in Inverted PSCs Be Reduced?

- Use of dibutyl sulfoxide (DBSO) in the bulk material to reduce defects

- Treatment of the surface of the perovskite film with trifluorocarbon-modified phenethylammonium iodide (2CF3-PEAI) to optimize energy levels and protect the film

- The use of additives, such as antisolvents and surfactants, to reduce the grain size of the perovskite film

- Improving the quality of the precursor solution by controlling the pH, temperature, and concentration of the solution

- The use of post-deposition treatments, such as thermal annealing and UV-ozone treatments, to reduce surface defects

- The use of protective layers to reduce moisture degradation and improve device stability

- The use of interlayers and charge transport layers to improve charge transport and reduce surface recombination

Also read