Automated chemistry collections new pace for materials discovery

- Scientists at the Division of Energy's Oak Ridge National Research Laboratory as well as the University of Tennessee are automating the search for brand-new materials to advance solar energy technologies.

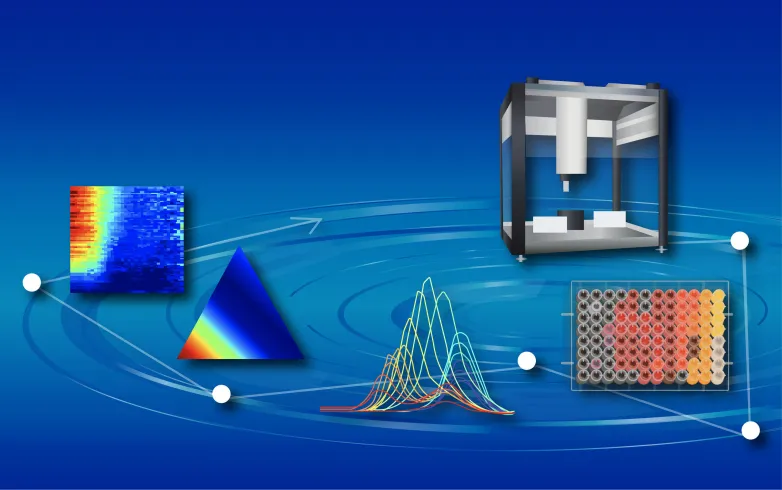

A novel process published in ACS Energy Letters combines robotics and machine learning to examine steel halide perovskites, or MHPs-- thin, light-weight, flexible materials with exceptional residential or commercial properties for utilizing light that can be used to make solar cells, energy-efficient lights as well as sensing units.

" Our method rates exploration of perovskite materials, making it significantly faster to synthesize and also characterize numerous material compositions at once as well as determine areas of rate of interest," claimed ORNL's Sergei Kalinin.

The research, part of an ORNL-UT Science Partnership partnership, intends to recognize one of the most stable MHP materials for device assimilation.

" Automated testing can assist us carve an efficient course forward in discovering what is an enormous swimming pool of possible product compositions," said UT's Mahshid Ahmadi.

Although MHPs are eye-catching for their high effectiveness and also low fabrication expenses, their sensitivity to the environment restricts functional usage. Real-world examples tend to weaken also rapidly in ambient problems, such as light, humidity or warm, to be functional.

The substantial capacity for perovskites presents an intrinsic barrier for products discovery. Scientists face a vast design space in their efforts to create more robust designs. More than a thousand MHPs have actually been predicted, and also each of these can be chemically modified to create a close to unlimited library of feasible compositions.

" It is hard to conquer this difficulty with conventional methods of synthesizing as well as identifying samples individually," said Ahmadi. "Our technique permits us to evaluate approximately 96 samples at a time to accelerate products exploration and optimization."

The team picked 4 version MHP systems-- producing 380 compositions complete-- to demonstrate the brand-new process for solution-processable materials, structures that start as damp combinations yet completely dry to solid forms.

The synthesis action employed a programmable pipetting robotic created to collaborate with common 96-well microplates. The machine conserves time over manually giving several structures; as well as it decreases mistake in duplicating a tiresome process that requires to be performed in specifically the very same ambient conditions, a variable that is challenging to manage over extended durations.

Next, researchers revealed samples to air and gauged their photoluminescent residential properties using a standard optical plate visitor.

" It's an easy measurement but is the de facto criterion for identifying stability in MHPs," stated Kalinin. "The key is that traditional methods would be labor intensive, whereas we were able to measure the photoluminescent properties of 96 examples in about five minutes."

Repeating the procedure over numerous hrs recorded complicated phase representations in which wavelengths of light differ across compositions as well as advance in time.

The group created a machine-learning formula to evaluate the data as well as home in on regions with high stability.

" Machine learning enables us to obtain more information out of sporadic data by anticipating homes between determined points," claimed ORNL's Adage Ziatdinov, that led development of the algorithm. "The outcomes guide materials characterization by showing us where to look following."

While the study focuses on products exploration to determine one of the most steady structures, the process might also be used to maximize product homes for certain optoelectronic applications.

The computerized process can be put on any type of solution-processable product for time and expense savings over typical synthesis approaches.

The journal article is released as "Chemical Robotics Enabled Exploration of Stability in Multicomponent Lead Halide Perovskites using Machine Learning."

Also read