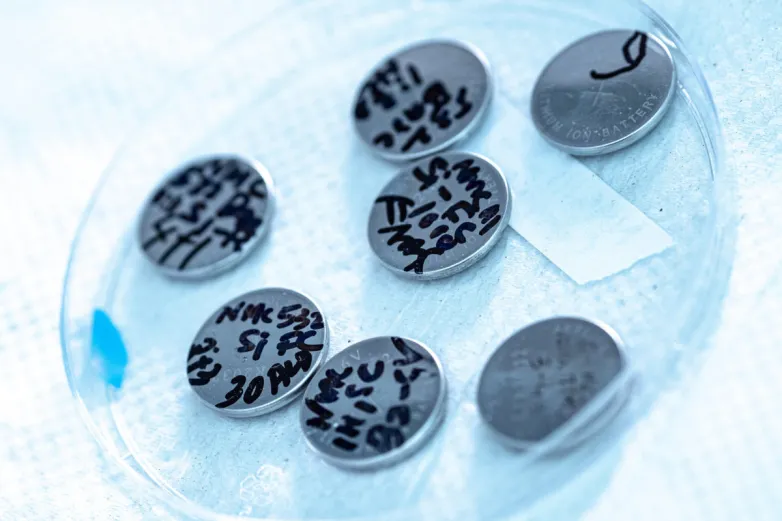

An alumina lining for silicon in storage

- Researchers at Rice University in the U.S. have actually carried out explores lithium-ion batteries using silicon as an anode product and made an unanticipated discovery relating to an aluminum oxide passivation layer at the cathode. The finding could open a brand-new pathway toward much better performing lithium-ion batteries.

Researchers at Rice University have actually made a discovery they say might open a path to new, extremely efficient battery design for grid storage, electric cars and other high energy applications.

The Houston-based researchers worked on changing the graphite anodes frequently seen in commercial lithium-ion batteries with silicon alternatives. Silicon anodes have possibly much greater capacity than graphite but the uptick features a catch: Silicon expands by approximately 400% as it alloys with lithium, leading loss of electrical contact and other potentially performance degrading problems.

Capacity increase

Graphite anodes normally have a capability of around 350 milliamp-hours per gram (mAh/g), while silicon weighs in at around ten times that –-- 3,580 mAh/g. The Rice scientists discovered that by making the silicon porous, and limiting the anode’& rsquo; s capability to 1,000 mAh/g, they had the ability to reduce much of the negative impacts.

“& ldquo; Optimum capability puts a lot of stress on the material so this is a strategy to get capability without the same degree of tension,” & rdquo; stated Sibani Lisa Biswal, chemical and biomolecular engineer at Rice University. “& ldquo; One thousand milliamp-hours per gram is still a huge dive.”

& rdquo; The group had the ability to integrate the silicon anode with a nickel manganese cobalt oxide (NMC) cathode to form a full-cell lithium-ion battery which demonstrated stability at 1,000 mAh/g over 580 cycles. The gadget is described in the paper ALD-Modified LiNi0.33 Mn0.33 Co0.33 O2 Matched with Macroporous Silicon for Lithium-Ion Batteries: An Examination on Lithium Trapping, Resistance Increase, and Cycle-Life Efficiency, published in Applied Energy Products.

Lithium trapping

A few of the NMC cathodes were coated in a three-nanometer thick layer of aluminum oxide, used utilizing atomic layer deposition. Examination of the role of the coating led the group to record a formerly unknown mechanism whereby lithium ended up being trapped in the finishing, restricting the number of times the battery might be charged and released.

Nevertheless, the scientists kept in mind, as soon as the finishing ended up being saturated with lithium and unable to take in any more the layer acted as a driver for fast transport to and from the cathode. “& ldquo; This lithium-trapping system efficiently protects the cathode by assisting keep a steady capability and energy density for the complete cells,” & rdquo; said Anulekha Haridas, a postdoctoral fellow at Rice.

The group said the discovery could open a pathway towards the efficient use of silicon-NMC batteries and the researchers will now focus on lowering lithium-ion loss in the electrolyte and improving the cycle life of the batteries.

Also read