Accuracy spray coating can make it possible for solar cells with far better performance as well as security

- Although perovskites are an encouraging alternative to the silicon made use of to make most of today's solar cells, brand-new manufacturing procedures are needed to make them sensible for commercial manufacturing. To aid fill this space, researchers have established a new precision spray-coating technique that enables a lot more complex perovskite solar cell layouts and also could be scaled up for automation.

Perovskites are promising for next-generation solar cells due to the fact that they absorb light as well as convert it to power with better efficiency as well as potentially reduced manufacturing prices than silicon. Perovskites can even be splashed onto glass to develop energy-producing windows.

" Our work demonstrates a process to down payment perovskite layer by layer with manageable densities and rates of deposition for each layer," said research study team leader Pongsakorn Kanjanaboos from the School of Materials Scientific Research as well as Technology, Professors of Scientific Research, Mahidol College in Thailand. "This brand-new method enables stacked layouts for solar cells with better efficiency as well as security."

In the Optical Culture (OSA) journal Optical Materials Express, Kanjanaboos and also colleagues describe their brand-new spray coating technique, called consecutive spray deposition, as well as reveal that it can be used to produce a multilayer perovskite layout. Applying different perovskite materials in each layer can allow customization of a gadget's function or the capacity to meet specific performance and also stability requirements.

A much better method to spray

One of the advantages of perovskites are that they are remedy processable, implying that a solar cell is made by drying fluid perovskite right into a strong at a low temperature. This fabrication process is a lot easier and also cheaper than making a conventional silicon solar cell, a procedure that needs really heats as well as cutting a strong material right into wafers.

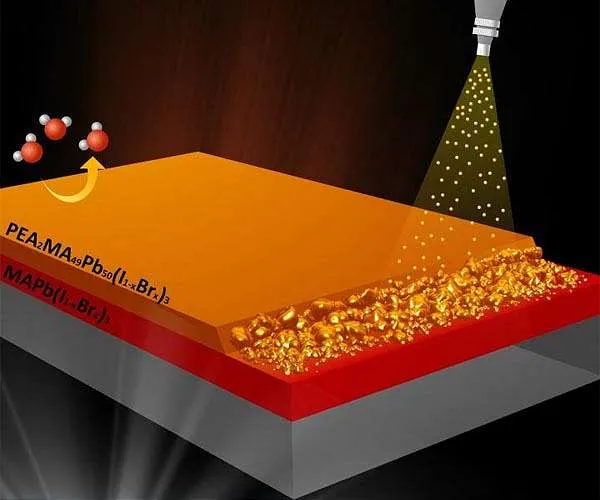

Nevertheless, the option procedure usually utilized to make perovskites does not allow multilayer styles since the upper layer often tends to liquify the already-dried reduced layer. To overcome this challenge, the scientists looked to a procedure referred to as sequential spray deposition in which tiny droplets of a material are applied to a surface area.

After trying various spray coating techniques, they found one that worked at temperature levels around 100 C. They after that maximized the spray criteria to guarantee that the small droplets dried and crystalized right into solid perovskite immediately upon contact with the already-dried lower layer.

Constructing a multi-layer device

" With our spray coating process, the option of the top layer doesn't disrupt the strong movie comprising the first layer," said Pongsakorn. "Endless combinations of piled perovskite designs with any kind of variety of layers can be made and developed with exact control of densities and prices of deposition for each layer."

The scientists demonstrated the strategy by depositing a perovskite product with high security on various perovskite material with far better electric residential or commercial properties. This double-layer semi-transparent perovskite tool proved defined layers and also simultaneously accomplished high performance and excellent security.

The researchers prepare to utilize the brand-new approach to make multilayer perovskite gadgets with new functions and also combinations of performance and also stability that were not possible prior to.

Also read