A jump in operation silicon for battery anodes

- The exact same product you'll locate at the idea of a pencil - graphite - has actually long been a vital element in today's lithium-ion batteries. As our dependence on these batteries boosts, nevertheless, graphite-based electrodes schedule for an upgrade. For that, researchers are seeking to the component at the heart of the electronic transformation: silicon

Researchers at the U.S. Department of Energy's Pacific Northwest National Laboratory have actually created an unique means to utilize this troublesome yet appealing power storage space component. Silicon, utilized in integrated circuit as well as several various other items, is appealing since it can hold 10 times the electric cost per gram contrasted to graphite. The problem is, silicon broadens significantly when it comes across lithium, and also it is also weak to hold up against the stress of electrode production.

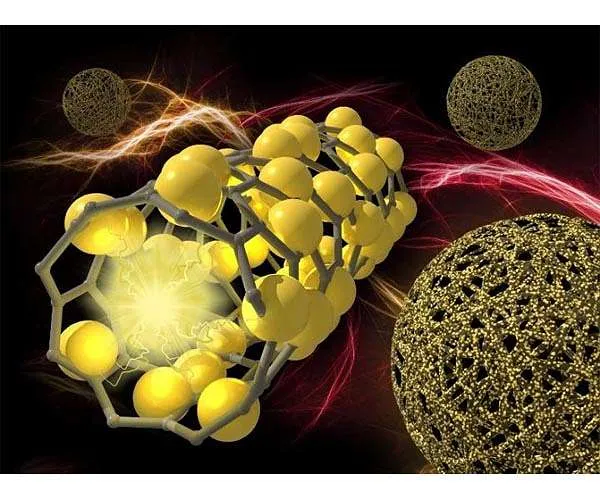

To deal with these concerns, a group led by PNNL scientists Ji-Guang (Jason) Zhang as well as Xiaolin Li established a distinct nanostructure that restricts silicon's growth while strengthening it with carbon.

Their job, which was lately released in the journal Nature Communications, can notify brand-new electrode product styles for various other kinds of batteries and also at some point assist boost the power capability of the lithium-ion batteries in electrical automobiles, digital tools, and also various other tools.

Taking the disadvantages out of silicon.

A secure and also conductive type of carbon, graphite is well matched to loading lithium ions right into a battery's anode as it bills. Silicon can handle even more lithium than graphite, yet it has a tendency to swell regarding 300 percent in quantity, creating the anode to disintegrate. The scientists produced a permeable kind of silicon by accumulating little silicon fragments right into microspheres concerning 8 micrometers in size - about the dimension of one red cell.

" A strong product like rock, for instance, will certainly damage if it broadens way too much in quantity," Zhang stated. "What we developed is extra sponge-like, where there is room inside to soak up the development."

The electrode with permeable silicon framework displays a modification in density of less than 20 percent while suiting two times the cost of a normal graphite anode, the research study located. Nonetheless, unlike previous variations of permeable silicon, the microspheres additionally showed amazing mechanical stamina, thanks to carbon nanotubes that make the balls appear like rounds of thread.

Super-strong microspheres

The scientists developed the framework in numerous actions, beginning by finish the carbon nanotubes with silicon oxide. Next off, the nanotubes were taken into a solution of oil and also water. After that they were heated up to steaming.

" The covered carbon nanotubes condense right into rounds when the water vaporizes," claimed Li. "Then we utilized light weight aluminum and also greater warm to transform the silicon oxide right into silicon, complied with by immersion in water and also acid to get rid of spin-offs." What arises from the procedure is a powder made up of the small silicon fragments externally of carbon nanotubes.

The permeable silicon rounds' stamina was checked making use of the probe of an atomic pressure microscopic lense. The writers located that of the nanosized thread spheres "might generate a little as well as shed some porosity under extremely high pressing pressure, yet it will certainly not damage."

This augurs well for commercialization, since anode products have to have the ability to manage high compression in rollers throughout production. The following action, Zhang stated, is to create even more affordable as well as scalable approaches for making the silicon microspheres to make sure that they can eventually make their means right into the future generation of high-performance lithium-ion batteries.

Also read