A closer check out graphene electrodes

- Scientists in the United States have found several imperfections in the strategies frequently utilized by researchers to design the structure of electrodes. The group outlines a new method which it says can bring about the exploration of new products and combinations that can lead to batteries performing much better for longer.

Composed of a few very tiny, nontransparent parts packed carefully with each other, taking a look at every one of the processes taking place inside a battery is not an easy task for scientists, as well as troubles in clearly observing as well as modeling a few of these processes is still a significant obstacle for research institutes.

Researchers at the University of Houston (UH) in the United States, dealing with funding from the U.S. Air Force Office of Scientific Research, considered one method that's commonly made use of in the computational modeling of battery electrodes, known as the porous media model, and kept in mind several imperfections that could bring about the inaccurate characterization of materials. Such designs, suggest the researchers, tend to presume harmony in the product's permeable framework, and also to overestimate ion diffusion residential or commercial properties.

" We intended to convey that the conventional models available, which are porous media-based designs, might not be exact sufficient for designing these brand-new nano-architectured materials and also checking out these products for electrodes or various other energy storage devices," stated UH Associate Professor Haleh Ardebili. "The porous media model might be convenient, yet it is not necessarily accurate. For modern gadgets, we require extra accurate designs to better understand and also create new electrode products."

The group showed one more approach, which replaces assumptions used in the porous media model with a strategy called nano-architecture computational modeling, which begins modeling at a smaller particle than others and takes into account various structuring of the materials at the nano range.

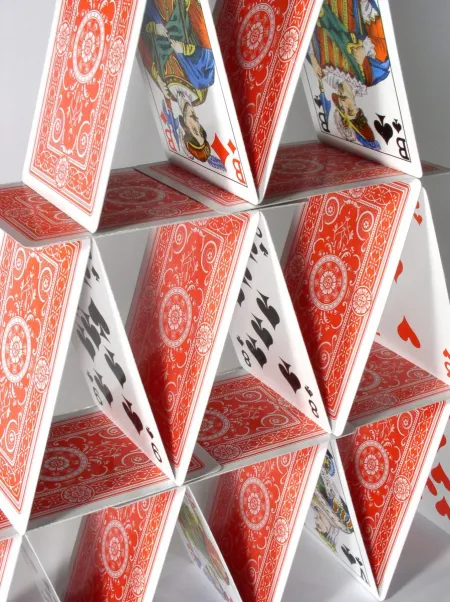

To confirm their design, the team designed two different nanostructures for an architectural supercapacitor electrode made from reduced graphene oxide as well as aramid nanofiber: a 'home of cards' and a 'split' framework. After computational modeling, the team sought to verify the designs by experimenting with the actual materials. Their outcomes, released in ACS Nano, demonstrated that this approach to modeling brings about a lot more exact assumptions.

The study revealed appealing characteristics for the graphene oxide/aramid nanofiber electrodes, which showed both good electrode performance as well as mechanical toughness. According to the researchers, this potentially makes the electrode suitable for a variety of use instances, including undefined army applications.

The team further notes that its modeling approach can assist to enhance understanding of product structures in a battery, inevitably resulting in much better items. "Evaluation of microscopic homes such as porosity, tortuosity, as well as effective diffusivity through both experiment as well as simulation is necessary to understand the material behavior and to enhance its efficiency," note the scientists in the released paper.

Also read