What is a Pogo Connector? Understanding Its Importance in Modern Electronics

In the world of modern electronics, there are countless components that make devices function seamlessly. One such component is the pogo connector. This small, yet essential part plays a vital role in the operation of many devices, from smartphones to medical equipment, to automotive applications. In this blog post, we’ll delve into what a pogo connector is, how it works, its applications, advantages, and why it’s such an important part of modern electronics.

What is a Pogo Connector?

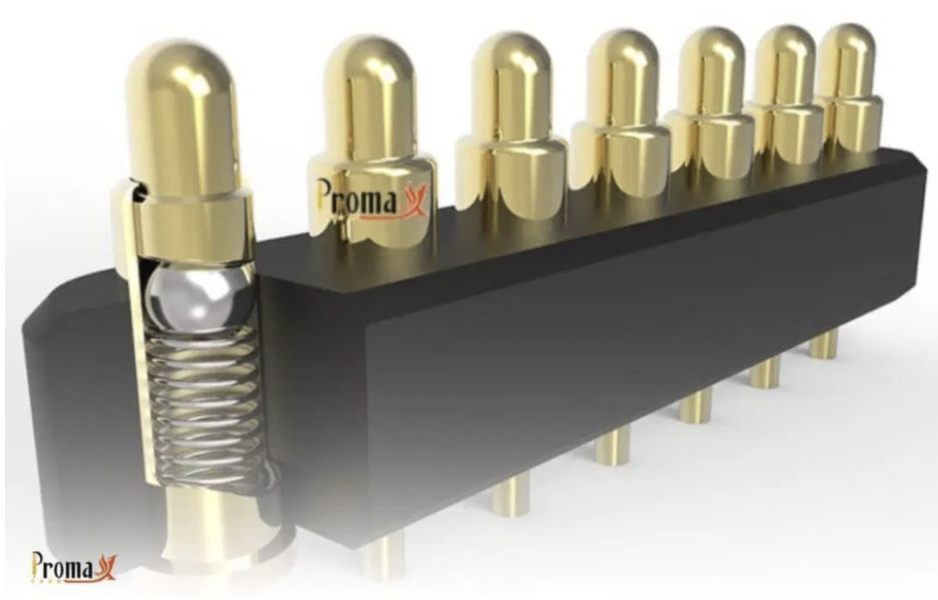

A pogo connector, also known as a pogo pin connector, is a spring-loaded electrical contact used in electronic devices for making temporary connections between two circuits. The name "pogo" comes from the pin's design, which is somewhat reminiscent of the pogo stick, bouncing back into place due to its spring mechanism.

These connectors are primarily used in applications where a reliable yet temporary electrical connection is needed. They consist of a pin (often made of metal) housed inside a spring. The spring provides tension, ensuring that the pin remains in contact with the corresponding part of the device, even when there’s some level of movement or vibration. Companies like Promax, a trusted pogo pin manufacturer, provide a wide range of pogo connectors tailored to specific needs, ensuring that devices stay connected even under challenging conditions.

How Does a Pogo Connector Work?

The operation of a pogo connector relies on its spring-loaded design. Essentially, the metal pin inside the housing pushes against a surface in a precise and controlled manner, creating an electrical connection. The spring allows the pin to move and maintain contact, which is crucial for ensuring continuous connectivity.

Here's a step-by-step breakdown of how a pogo connector works:

-

Pin and Spring Mechanism: The pogo connector consists of a pin (usually made of conductive material) inside a spring.

-

Contact with Counterpart: The pin makes contact with another conductive part of the device. This part could be a copper pad, circuit board, or another pogo pin.

-

Spring Tension: The spring inside the connector ensures that the pin maintains consistent contact, even when there are small shifts or vibrations in the surrounding environment.

-

Electrical Connection: When the pin touches the conductive surface, it completes the electrical circuit, allowing electricity to flow from one part to another.

This design allows pogo connectors to deliver temporary yet reliable electrical connections, which makes them indispensable in many industries.

Types of Pogo Connectors

Pogo connectors come in various types, each designed for specific applications and requirements. The most common types include:

1. Standard Pogo Pins

Standard pogo pins are the most common type of pogo connector and are often used in a wide range of consumer and industrial applications. These connectors consist of a single spring-loaded pin that provides a reliable and temporary electrical connection. Standard pogo pins are popular due to their simplicity and cost-effectiveness, making them ideal for applications where space is limited and the need for a quick connection is paramount. They are typically made from materials like stainless steel or brass, with gold or nickel plating to enhance durability and reduce the risk of corrosion. While they may not be as robust as their high-current counterparts, standard pogo pins are perfectly suited for low-power electronics, such as testing devices, small appliances, and charging stations for portable gadgets.

2. Dual Pogo Pins

Dual pogo pins offer enhanced stability and reliability compared to standard single-pin connectors. These connectors feature two spring-loaded pins that provide more consistent electrical contact, making them particularly suitable for applications that require a higher degree of precision and stability in the connection. By using two pins, dual pogo connectors are better equipped to handle fluctuations in alignment and contact pressure, which can occur in dynamic environments or devices that are subject to physical movement. These types of connectors are widely used in more complex consumer electronics, such as portable battery chargers, medical devices, and industrial equipment. They also offer better performance in situations where consistent and reliable data transmission or power delivery is essential.

3. Custom Pogo Pins

Custom pogo pins are designed to meet specific and unique requirements, offering tailor-made solutions for specialized applications. Unlike standard pogo pins, which come in predefined sizes and configurations, custom pogo pins can be engineered with specific materials, shapes, sizes, and even configurations to suit a particular device or design. This level of customization ensures that the connector can meet the exact electrical and mechanical needs of the application, whether it involves extreme environmental conditions, high precision, or unique physical space constraints. Custom pogo pins are often used in high-end electronics, military and aerospace applications, and custom-built testing devices, where standard connectors would not suffice. The ability to fine-tune every aspect of the pogo connector makes them invaluable for creating highly specialized or cutting-edge technologies.

4. High Current Pogo Connectors

High current pogo connectors are designed to handle large amounts of electrical power, making them essential for applications that require substantial voltage and amperage. These connectors are built with thicker and more robust materials, often featuring higher-grade metals such as copper or alloys that can withstand the increased power demands without overheating or degrading. High current pogo pins are used in high-power charging stations, such as those for electric vehicles (EVs), power supply systems, and industrial automation equipment, where standard connectors may not be capable of managing the power load. These connectors are engineered with advanced designs to ensure reliable performance even under heavy electrical stress, making them indispensable in applications where both high power and temporary connection capabilities are critical. Their reliability and performance make them a popular choice for applications where safety and durability are of utmost importance.

Common Applications of Pogo Connectors

Pogo connectors are used across various industries, often in devices where a temporary electrical connection is needed. Some of the most common applications include:

1. Consumer Electronics

-

Smartphones: Pogo connectors are commonly used in charging docks and docking stations for smartphones and tablets.

-

Wearable Devices: Many smartwatches and fitness trackers use pogo connectors for charging or data transmission.

-

Laptops: Laptops with detachable keyboards or docking stations often utilize pogo pins for their connectivity.

2. Medical Equipment

-

Diagnostic Devices: Pogo connectors are used in diagnostic tools and portable medical equipment, enabling reliable connections for testing and charging.

-

Wearable Health Devices: Devices such as heart rate monitors or insulin pumps also rely on pogo connectors for charging and data communication.

3. Automotive Industry

-

Electric Vehicles (EVs): Pogo connectors are used in charging stations for EVs, allowing easy connections for high-current charging.

-

Vehicle Assembly: They’re also used in assembly lines, where temporary electrical connections are needed during the assembly process.

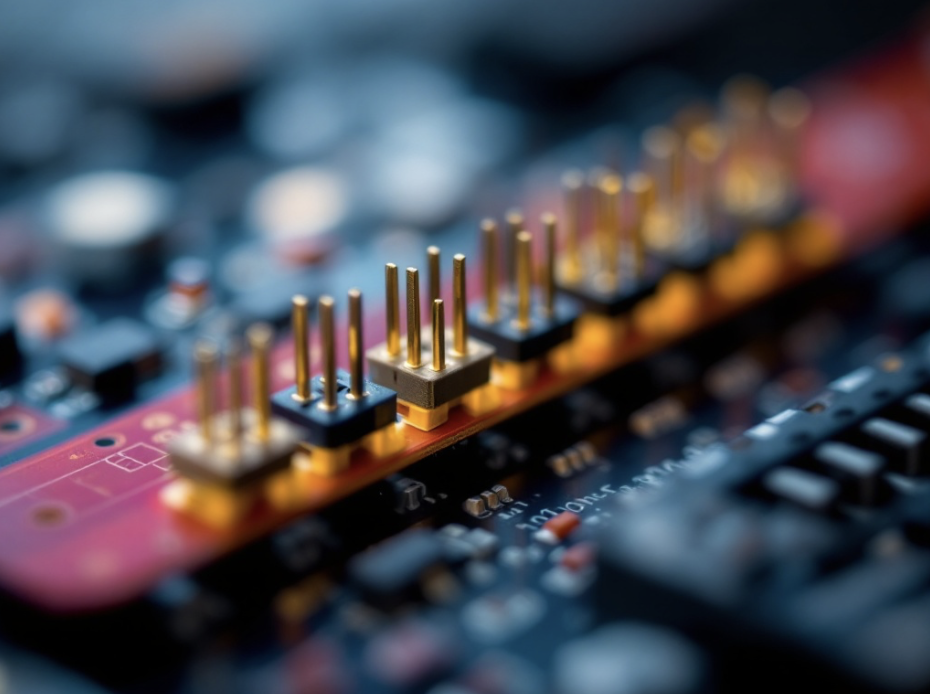

4. Test Equipment

-

Testing Circuits: Pogo connectors are widely used in testing equipment, where temporary connections to circuit boards are required without permanent attachment.

-

Prototyping: Engineers use pogo connectors during the prototyping phase to test various electronic devices before final assembly.

Advantages of Pogo Connectors

The versatility and functionality of pogo connectors make them ideal for many applications. Below are some key advantages of using pogo connectors:

-

Compact and Space-Efficient: Their small size makes them perfect for applications where space is limited.

-

Reliable Connectivity: The spring-loaded design ensures that the pin maintains consistent contact with the counterpart, even in the presence of vibrations or slight movements.

-

Durability: Pogo connectors are durable and can withstand repeated use without losing their effectiveness.

-

Ease of Use: They allow for quick and easy connections, reducing the need for soldering or complex wiring.

-

Cost-Effective: Pogo connectors are often more affordable than permanent connectors, especially in mass-production environments.

Factors to Consider When Choosing Pogo Connectors

When selecting a pogo connector for your project or device, there are several factors to consider to ensure the best performance:

1. Current and Voltage Requirements

Make sure that the pogo pin you choose can handle the required electrical load for your device. Some connectors are designed for high current applications, while others are more suited for low-power electronics.

2. Size and Form Factor

Choose a pogo connector that fits your design specifications. Since they are used in compact devices, you may need to consider the size and space available for the connector.

3. Contact Material

The material of the pin and the spring can affect the durability and performance of the connector. Gold, for example, is often used for high-end connectors because of its corrosion resistance.

4. Environmental Factors

Consider the conditions in which the pogo connector will operate. If your device is exposed to extreme temperatures, moisture, or other harsh conditions, you may need to choose a connector with special protective coatings or seals.

How to Maintain Pogo Connectors

To ensure that pogo connectors continue to function properly throughout their lifespan, it’s important to take some maintenance steps. Here’s a brief guide on maintaining pogo connectors:

1. Regular Inspection

Periodically check the pogo pins for signs of wear and tear. If the spring tension becomes weak, the connector may not make reliable contact.

2. Clean the Contacts

Dust and dirt can accumulate on the pogo pins, affecting the electrical connection. Clean the pins using a soft brush or cloth to remove any debris.

3. Check for Corrosion

Corrosion can damage the metal contacts, leading to poor connectivity. Inspect the connectors regularly for signs of rust or oxidation, especially in environments with high humidity or salt exposure.

4. Ensure Proper Alignment

Ensure that the pogo connector remains properly aligned with the counterpart connection to avoid misalignment, which could cause intermittent connection failures.

Conclusion

Pogo connectors are an indispensable component in the modern electronic world, providing reliable and temporary electrical connections in a variety of applications. From consumer electronics and medical devices to automotive and testing equipment, these connectors offer exceptional durability, ease of use, and space efficiency. Whether you're developing a new gadget, testing circuits, or working in an industrial environment, understanding and utilizing pogo connectors can significantly improve the performance and reliability of your devices.

By choosing the right type of pogo connector and ensuring proper maintenance, you can maximize the effectiveness of your electronic devices and systems. The versatility and functionality of pogo connectors make them an essential part of the modern electronics landscape.

Also read

- Home EV Charging Stations in Ireland: How Much Can You Really Save?

- Automated File Conversion Services: Transform Documents Without Manual Work

- The Rapid Evolution of Direct Current Fast Charging for Electric Vehicle Fleets

- Scaling Data-Driven Campaigns Without Breaking Your Stack

- The 12th World Sustainability Forum (WSF-12)