Utilizing nanowires to make ultra reliable affordable solar cells

- A research study group at the Norwegian University of Science and also Technology (NTNU) has actually established a method for making an ultra-high product reliable solar cell using semiconductor nanowires. If this is positioned on top of a typical silicon-based solar cell, it can possibly double the performance of today's Si solar cells at low cost.

" We have a new approach of using gallium arsenide (GaAs) product in an extremely reliable means via nanostructuring, so we can make solar cells a lot more effective using just a little portion of the material that is usually utilized," claims Anjan Mukherjee, a PhD prospect at the Department of Electronic Systems.

Mukherjee is the major designer of the technique.Gallium arsenide (GaAs) is the very best material for making high performance solar cells because of its remarkable light absorption and also electric features. It is typically used to make solar panels primarily for use precede.

Nonetheless, top quality GaAs solar cell elements are quite expensive to make, which has actually driven a demand for strategies that can cut making use of the product.

Over the last few years, scientists have understood that a nanowire framework can potentially boost solar cell efficiency contrasted to common planar solar cells, also as the method makes use of much less product.

" Our research team has discovered a new method to make an ultrahigh power-per-weight proportion solar cell that is more than 10 times extra reliable than any other solar cell, by using GaAs in a nanowire structure," says Helge Weman, a teacher at the Department of Electronic Systems at NTNU.

Pioneering technique

GaAs solar cells are most often expanded on a thick as well as expensive GaAs substratum, which leaves little area for reducing costs.

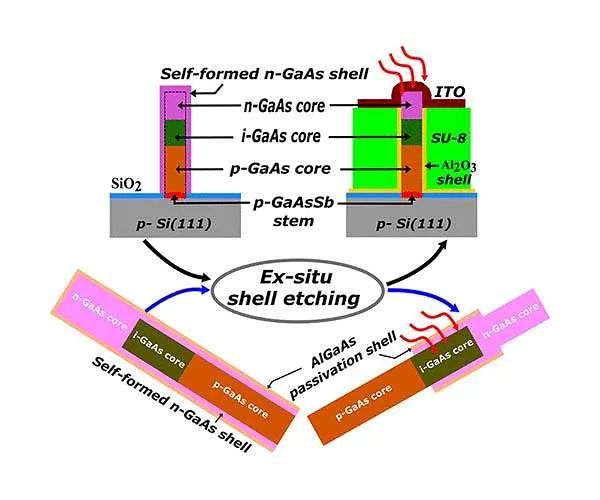

" Our approach uses a vertically standing semiconductor nanowire variety structure on a low-cost and also industry-favorable Si system to grow the nanowires," Weman said.

" One of the most economical as well as reliable option is to expand a dual tandem cell, with a GaAs nanowire cell on the top expanded on a bottom Si cell, which avoids using a costly GaAs substrate. We have worked to minimize the cost of growing the leading GaAs nanowire cell, because it's the GaAs manufacture price that is just one of the significant concerns that is presently keeping back the technology," Weman describes.

" The tiny footprint of the nanowire framework gives an additional benefit, because it enables excellent quality in crystals in the nanowire as well as in the interface with the silicon. This helps boost the solar cell efficiency," said Bjorn-Ove Fimland, a teacher in the exact same department.

The advancement of this technology can be straightforward and also cost-efficient with suitable financial investments as well as industrial-scale R and also D projects.

" We grow the nanowires making use of a technique called MBE (molecular light beam epitaxy), which is not a device that can create materials at a high volume. Nevertheless, it's possible to create these nanowire-based solar cells at a huge scale by using an industrial-scale tool such as MOCVD (steel natural vapor deposition)," Mukherjee stated.

Integrating this item in addition to a Si cell can potentially improve solar cell efficiency to as much as 40 % - which would certainly indicate an increasing of efficiency when compared to today's business Si solar cells.

Appropriate for space travel

The scientists say their method could be adjusted so that the nanowires are expanded on different substratums, which can open the door to many other applications.

"We are discovering expanding this type of light-weight nanowire structure on atomically slim two-dimensional substratums such as graphene. This can open up substantial chances to create light-weight and flexible solar cells that can be made use of in self-powered drones, micro-satellites and also other area applications," Mukherjee said.

The team's research has actually been published in ACS Photonics, a journal from the American Chemical Society.

Also read