Unique Stellio Heliostat Solar Project Goes Online in China

- Among the globe's initial molten salt tower focused solar energy (CSP) projects that utilizes a "Stellio" heliostat was grid-connected at the end of December in China's Xinjiang district near the Mongolian boundary. The 50-MW Hami pilot project established by Chinese state-owned firm China Power Engineering Consulting Group notes a significant turning point for the unique heliostat layout, which went from idea to building in a simple 5 years.

The $226 million Hami project is a main receiver plant that utilizes liquified salts as warm transfer liquid and also as a thermal storage space system. According to its developer, the project runs with a 43% thermal effectiveness under ambient temperature levels of 19C, as well as an air condenser backpressure of 8.5 kPa. When in operation, the thermal effectiveness of the thermal storage space as well as warmth transfer system gets to 99%-- which suggests the 1,430 MWh storage space system can run the generator at complete result for 12 hrs.

The Hami project, which was constructed in about 2 years, is China's 6th massive business solar thermal power project, according to the China Solar Thermal Alliance, and also it brings the nation's overall CSP ability to 350 MW. Nevertheless, advancement of its ingenious heliostat started a lot earlier.

According to a current paper authored by professionals associated with the Hami project, the layout principle materialized when German architectural design and also consulting company Schlaich Bergermann Partner (sbp) laid out to resolve a raising passion in solar tower modern technology in 2010. The company partnered with South Africa's SASOL Technology to more create its style, and also the companions ultimately picked calling it "Stellio," a name that describes a sun-loving agama reptile.

Sdp signed up with pressures with Spanish CSP professionals Ingemetal Energias and also Masermic when SASOL took out from renewables to concentrate on its chemicals organisation. The business developed the initial Stellio model (Figure 2) at the Plataforma Solar de Almería in Spain in 2014, furnishing it with sensing units. That project, sdp stated, permitted and also verified for confirmation of Stellio's "impressive optical and also monitoring efficiency." A minimum of 4 various other models were likewise examined, each structure on lessons discovered.

Nonetheless, the consortium's preliminary initiatives to develop a first-of-its-kind plant at Redstone in South Africa's Northern Cape Region fell down, so it teamed up with Dongfang Boiler Group (DBC), as well as at some point won a tender in 2016 to construct a project at the Hami solar area. As sdp notes, Stellio was specifically appealing also after that; it won the SolarPACES Technology Innovation Award 2015 as well as the CSP PLAZA Technology Innovation Award 2017.

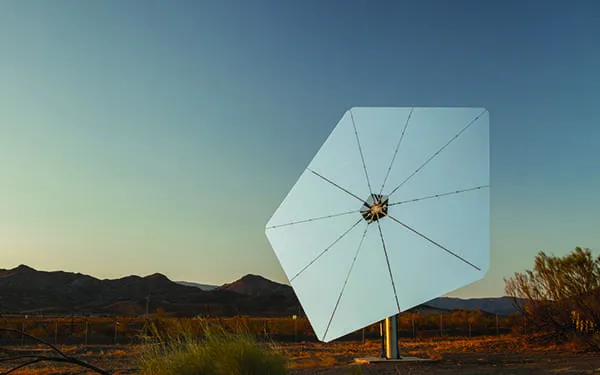

Its winning characteristic is its pentagonal layout, which substantially lowers the continuous however refined oscillation from wind lots. The layout basically consists of 10 cantilever arms as well as a main center, which enables "a much more identical tightness circulation contrasted to rectangle-shaped frameworks as well as lead to an extremely reliable architectural system, [that is], it gives reduced contortions as well as therefore high optical efficiency at reduced details weight. Its roundish form minimizes obstructing and also shielding as well as permits a portable area format," the company clarified.

Nonetheless, the layout is additionally partially stemmed from well-proven allegorical trough modern technology. "The cantilever arm [is] bonded from hollow box areas-- very easy to make as well as with maximum tightness per weight." It likewise includes 5 rings of purlins that lug the mirrors; the purlins are made from an economical sheet steel. The center as well as the parts of the kinematic system are bonded from plates.

" The major benefit of the Stellio kinematic system with 2 likely axes is that cost-effective direct actuators can be made use of for both axes which tracking mistakes because of drive reaction are gotten rid of for [most] heliostat alignments," sdp included.

The entire framework is after that warm dip galvanized to make certain lasting deterioration defense. Ultimately, it makes use of 10 mirrors (made from 4-millimeter-thick float glass) along with a main mirror-- which entirely create a 48.5-square-meter showing surface area. The Hami solar area ended up being preferably matched to the Stellio style due to the fact that it includes a "mild general incline" that offers well to a staggered area arrangement. The area bordering the 94-meter-high solar tower can organize 14,500 heliostats.

According to SolarPACES, the International Energy Agency's CSP study arm, exactly how swiftly the idea proceeded from "laboratory to industrial" is impressive. "The largest barrier to progressing possible cost-cutting renovations in unique CSP innovations is obtaining them released in industrial projects. Dangers are high when every CSP plant have to be constructed at utility-scale as well as need to earn money today," it kept in mind. Nonetheless, the project additionally profited considerably from being constructed in China, which as Solar PACES kept in mind, "takes a various technique to brand-new innovations that prefers offering unique styles a trial run. Its initial CSP projects are presentation projects, yet they are being developed at complete dimension to permit real-life design concerns to appear so they can be fixed at business range."

The 50-MW Yumen project in China, for instance, is checking a "beam-down" meal CSP, an innovation that guarantees to reduce CSP power expenses by 30%. "If beam of light down jobs, it can substantially streamline solar hydrogen thermochemistry, since a prime focus on the ground contributes to an additional advancement to reduce sustainable hydrogen expenses by incorporating the solar receiver/reactor with thermal storage space at ground degree, where the thermochemistry for splitting water is finest performed," the company kept in mind. One more stage of the Yumen project is additionally checking a silicon-based warmth transfer liquid (HTF) for trough CSP in a project pioneered by Chinese company Royal Tech CSP, one more SolarPACES honor champion. That's remarkable due to the fact that "Silicon can obtain much hotter than today's 400C criterion warm transfer liquid for trough CSP, so this Si-HTF significantly enhances the effectiveness of allegorical trough CSP," SolarPACES claimed.

Also read

- UbiQD Secures Landmark Quantum Dot Deal with First Solar

- Astronergy Invests $53M in Tandem Solar Cell Project

- ARENA Unveils $39M Solar Innovation Funding Round

- CNNP Optoelectronics brings utility-scale perovskite modules out of the lab

- Low-Temperature Sequential Deposition Lifts Inverted Perovskite Solar Cells Efficiency Record