TruSpin Reveals Breakthrough in Lithium-ion Battery Modern Technology

- Third-party tests have verified that making use of TruSpin silicon nanofibers reliably multiplies the power ability of Lithium-ion batteries.

TruSpin Nanomaterial Innovation, an advanced materials company participated in battery modern technology, has revealed the favorable results of third-party tests reviewing the performance of the firm's model batteries. The tests, conducted by SpectraPower, confirm making use of TruSpin's silicon nanofibers to accurately increase the power capability of Lithium-ion batteries.

"These results provide more confirmation of our product's capability to accurately increase the power capability of Li-ion batteries. The introduction of this innovation challenges previous time perspectives for the extensive fostering of electric automobiles and also tidy energy resources," claimed Robert Agnew, CEO of TruSpin.

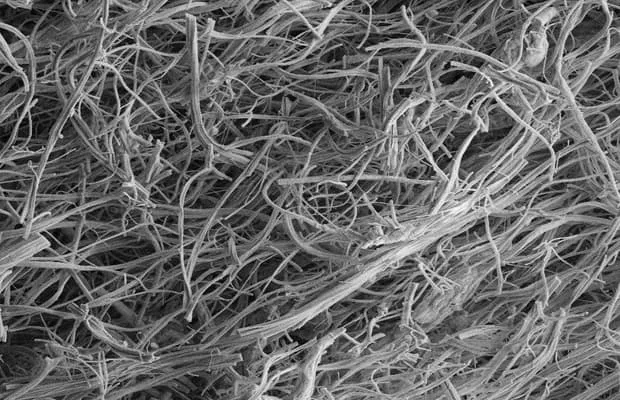

The company utilizes an exclusive process to mass produce unique compositions of nanofibers, a brand-new kind of product with beneficial buildings. Their prototype batteries incorporate silicon nanofibers within the adverse side of the battery, referred to as the "anode." For years, scientists have recognized that using silicon by doing this raises the power capability of batteries, however they're challenged by silicon's tendency to expand as the battery costs. Because of this, firms like Tesla use a fairly small amount of silicon in their batteries. A handful of startups concentrated on silicon anode technology offer other types of nano products to raise the silicon material. They have actually drawn in large investments, but the intricacies of their production techniques render these solutions financially not practical.

TruSpin declares it is separated by its system manufacturing process for affordably mass-producing nanofibers. While the methods of various other firms in the silicon anode segment include engineering elaborate silicon fragments on the nano-scale, TruSpin's manufacturing technique imparts the preferred features to be innately embodied by the nanofibers. This makes it possible for the industrial-scale fabrication of anodes containing silicon nanofibers as the key constituent.

"Before these tests, we believed that cells deploying TruSpin's materials within the anode would increase capacity without the compromises normally associated with silicon. We proved it with these prototypes and further concluded that TruSpin's silicon nanofibers can be expected to perform competitively with solutions offered by the leaders in silicon anode tech. That's monumental. Now it's time to prove the upper limits of performance in cell architectures optimized for specific use cases. That means prototyping with both feet on the gas. Hopefully, this will be in collaboration with a major stakeholder in battery tech- a company that stands to gain a competitive advantage by improving the performance of the batteries used in their products. In the long term, it's all about proving the engineering pathway to industrial-scale production. We've accomplished every goal we've set so far by driving hard to hit milestones with deadlines a larger firm wouldn't dream of. Expect more of the same." he told Saur.

Also read