Towards circular business models for the PV sector

Nov 1, 2019 07:54 PM ET

- With solar energy about to reach the iconic terawatt (TW) milestone of globally installed PV capacity, waste handling and end-of-life (EoL) scenarios become a pressing matter.

The solar photovoltaic (PV) energy industry is experiencing radical growth. Nearly 80% of the worldwide PV installations have been deployed during the last five years alone, and cumulative installed PV capacity today exceeds 500 GWp. This figure is expected to overtake 1 TWp peak by 2022.

On the shadow side of this success, the number of PV modules that will reach the end of their useful first-life will also greatly increase. Without effective end-of-life management, they will accumulate proportionately as PV waste. Studies estimate that global PV waste could reach up to eight million tons by the end of 2030 and even a tenfold cumulative of up to eighty million tons by 2050. This does not take into account the waste originating at the production level, or resulting from installations being decommissioned before their ‘technological retirement age’ (e.g. because of insurance claims, repowering, etc.). For comparison, the amount of waste resulting from plastic packaging in Europe alone surpasses 15 million tons annually.

Rather than considering this a mountain too high to climb, the PV sector and affiliated stakeholders are already looking at this evolution as an upcoming era of opportunity, potentially leading to new financing mechanisms and multiple revenue streams across the whole PV value chain. Not coincidentally, significant shifts in R&D efforts and business attention can be observed towards streamlined PV operations and maintenance (O&M), to ensure maximum and cost-efficient first-life operation of PV components. Sustainable (profitable) EoL management and repair procedures are also a focus, to establish long-term and competitive performance and reliability during their potential second life.

Myriad possible approaches

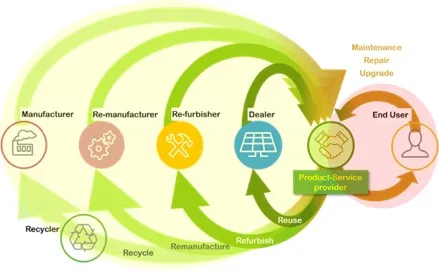

PV recycling, recovery of raw materials, repair or refurbishment of decommissioned, failed or degraded PV modules and their recommissioning (second-life PV modules), are indispensable for a more sustainable, environmentally friendly and economically viable solar PV energy-based future.

Research has already been conducted and decision trees already exist to navigate these different options of EoL management. Yet, insights from the reported literature have been rather fragmented and somewhat one-sided. Indeed, they largely focus on PV recycling processes and related innovation efforts, leaving the potential value of PV re-use relatively unexplored. Knowledge or best practices in repair/refurbishment, reliability and certification/qualification of second-life PV modules have been scarce, and there is even less knowledge and awareness about the opportunities for additional value creation via circular business models. For example, by more closely involving the original manufacturers and downstream stakeholders in relevant parts of EoL processes.

CIRCUSOL sheds light on the matter

CIRCUSOL (short for ‘circular business models for the solar power industry’) is an Innovation Action project funded by the Horizon 2020 program of the European Commission. Coordinated by VITO (Flemish Institute for Technological Research), it brings together 15 partners from seven different countries. Established in 2018 for a period of four years, the program aspires to formalize the various EoL segments in the PV value chains and to propose adapted technical standards and regularity frameworks for them. Based on this knowledge, the program aims to develop and validate a Product-Service System (PSS) that enables the implementation of circular business models throughout the value chain.

First insights from the program already prove to be highly valuable. Today, by default, once PV modules are decommissioned, they enter the waste stream and are either disposed of or recycled. Because most PV installations are still relatively far from reaching their expected end of life, the majority of today’s PV waste still results from product defects upon production, transportation or infant failures over the first four operational years. CIRCUSOL partners and experts estimate that around half of the PV modules that enter the waste stream can actually be repaired or refurbished and reused. CIRCUSOL has made a comprehensive overview of the current status of players active in the various EoL scenarios, as well as the state-of-the-art in supporting technologies and business models.

A little legislative push

Those familiar with the PV sector will recognize that repair and refurbishment at present remain rather informal and are neither systemized nor standardized. In fact, these activities are currently performed by independent private companies, without any support from the original manufacturers. On this basis, today, there are only limited insights and hardly any standards on the characterization, reliability testing, certification or labeling for second-life PV modules. Yet, from a functional perspective and in view of the Low Voltage Directive (LVD) (2014/35/EU), relevant conformity assessment and safety requirements are still applicable, also for second-life PV modules.

Aside from this, the Waste Electrical and Electronic Equipment (WEEE) Directive (2012/19/EU) addresses the waste management requirements of all electronics’ waste in the EU member states. Indicating a 85/80 (%) recovery/recycling ratio of waste PV modules by mass should be recycled from 2019 onwards. It’s no secret that EoL and recycling technologies must evolve and become available to meet the increasing requirements of WEEE for the case of PV waste.

Joint effort to harvest future potential

All in all sufficient reasons for the PV sector and related stakeholders to put their shoulders under the challenges that need to be tackled and jointly reap the benefits of the various opportunities lying ahead. This includes, but is certainly not limited to, assessment and validation of PV design-for-recyclability and design-for-repairability concepts; development of tailored, cost-efficient reliability testing and characterization protocols for second-life PV modules; cost-profit and life cycle analysis for the PV re-use (i.e. second-life) business case.

Also read