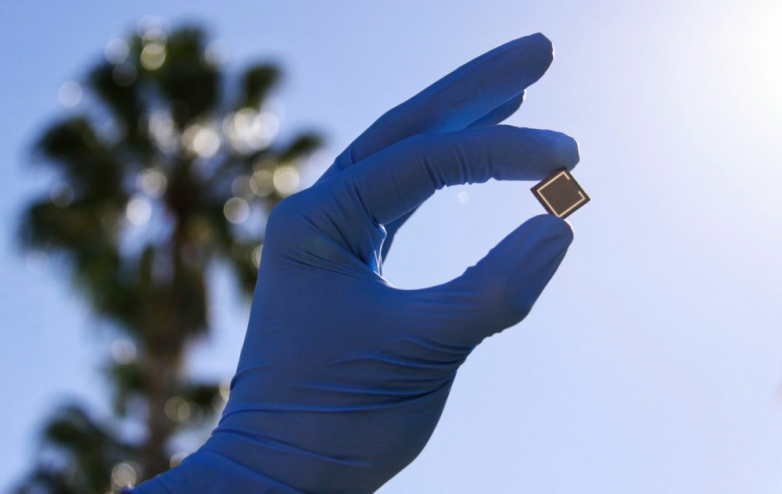

Toledo Uni Scientists Make 6.4% Effective Antimony Selenide Solar Cell

- In a paper entitled 'Influence of Post-selenization Temperature Level on the Performance of Substrate-Type Sb2Se3 Solar Cells', published in the peer-reviewed journal ACS Publications (whose parent organisation is American Chemical Society), scientists working at the University of Toledo in the USA have actually developed a 6.43%-efficient solar cell utilizing antimony selenide (Sb2Se3) films with favourable crystalline properties.

For achieving such a high conversion effectiveness for this early-stage PV material, they concentrated on the selenization temperature level. Although antimony selenide is not a well researched absorber product, it has a near-direct bandgap of ~ 1.2 eV and also superb optoelectronic homes, just the same. The researchers claimed that the cell they made is "a low-cost as well as eco-friendly gadget", and was made by depositing the Sb2Se3 films on soda-lime glass substratums covered with molybdenum (Mo) making use of shut room sublimation (CSS). The latter is a physical vapor deposition process, and prevails in the production of thin-films as well as cadmium telluride (CdTe) panels.

A bulk Sb2Se3 absorber layer was deposited utilizing the resource plate. The researchers explained that the gotten absorber layers were then selenized at temperatures from 350 to 450 levels Celsius in argon at a base pressure of 10 Torr with 100 mg selenium for thirty minutes to promote the recrystallization of Sb2Se3. Upon the verdict of this manufacturing action, the academics deposited a 55 nano-meter thick cadmium sulfide (CdS) barrier layer onto the absorber utilizing chemical bath deposition. After that was deposited a front contact layer making up a 50 nm high-resistive intrinsic zinc oxide (i-ZnO) layer and also a 250 nm aluminum-doped zinc oxide (ZnO: Al) through superhigh frequency (RF) sputtering. Once all these layers were scribed together, they formed a solar cell with an active location of 0.2 cm ². According to the researchers, the outcomes of the experiment indicate that an appropriate selenization temperature is essential to accomplishing Sb2Se3 films with big grains, uniform morphology, high crystallinity, wanted crystal orientations, as well as raised carrier thickness. They concluded that by enhancing the selenization temperature, they got Sb2Se3 solar cells with a power-conversion efficiency of 6.43%.

The writers of the paper consist of Suman Rijal, Deng-Bing Li, Rasha A. Awni, Sandip S. Bista, Zhaoning Tune, and Yanfa Yan.

Also read

- Revolutionizing Solar Energy: Key to Efficient Organic Cells

- Revolutionary Solar Cells Power Drone with Unprecedented Efficiency

- Unlocking Perovskite Secrets: Next-Gen Solar Cell Breakthrough

- Ultra-lightweight Perovskite Solar Cells Power Energy-Autonomous Drones

- Revolutionary CFS Technique for Rapid Perovskite Solar Cells